In line with gasification

Current in the fall of JSC "Autodiesel" started the serial production of gas engines of the family YAMZ‑530 CNG.

in the Fall of 2016 Yaroslavl motor plant (YAMZ), he of "Autodiesel" has started to the serial production of gas engines of the family YAMZ‑530 CNG.

The start of the project is timed to the 100th anniversary JAMZ, which today is one of the largest Russian manufacturers of engines. Today, the vast production program of the enterprise includes medium and heavy diesel engines, light clutch and gearbox. With this over 69% of power plants of the Yaroslavl sent to the manufacturers of commercial vehicles in Russia and the CIS countries.

Gas path

As you know, in this year the"Avtodizel" organized serial production of engines JAMZ‑530 corresponding to the level of Euro‑5. Now it's the turn to engine compressed natural gas (compressed natural gas, CNG). Due to the high standardization of a new power plant of YAMZ‑530 CNG appeared in deadlines with minimal cash investment. The use of technology, working on the methane can provide a level of operating costs 40-50% lower than diesel gasoline and also reduce emissions of carbon monoxide in 5-6 times.

Gas engine YAMZ-534 CNG

In middle row of four - and six-cylinder engines YAMZ‑530 CNG, relevant environmental standards Euro‑5, engineered with advanced technical solutions for the arrangement, control and operation of the main systems that ensure their reliable and efficiency. Gas engines YAMZ‑534 CNG (150-170 L.C.) and YAMZ‑536 (CNG 258-312 HP) developed with the assistance of a number of foreign companies.

Gas six-cylinder YAMZ-536 CNG

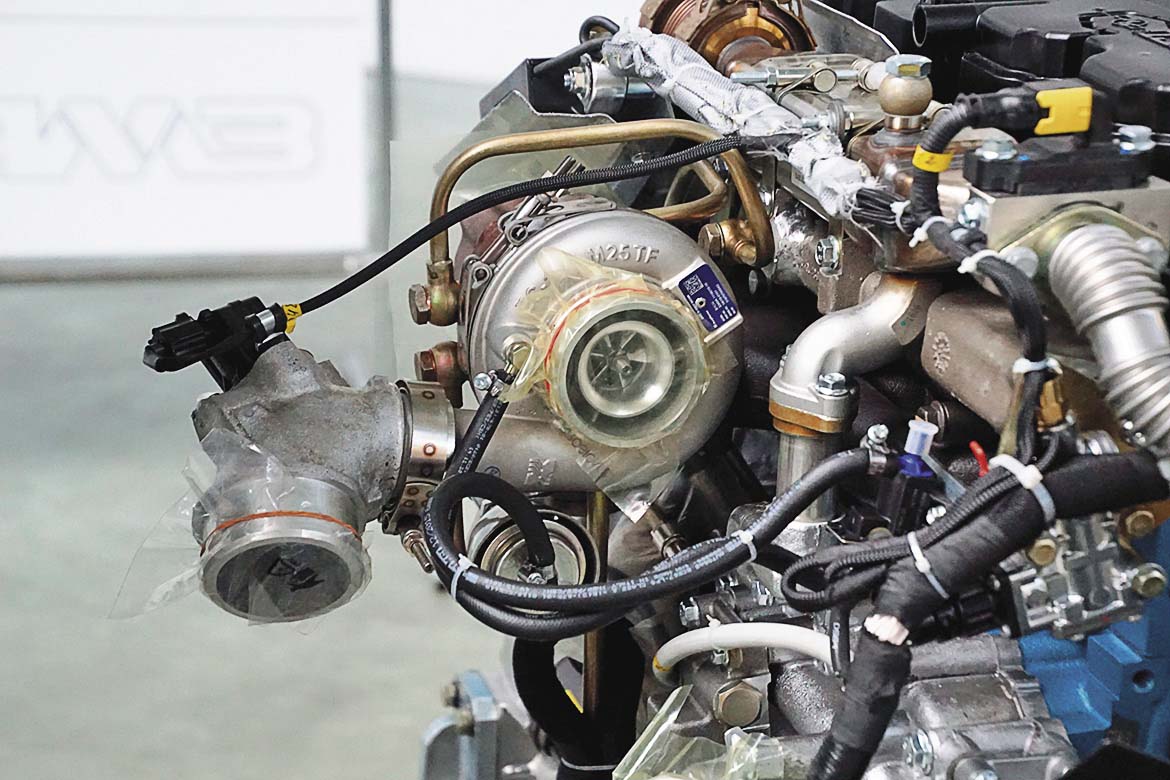

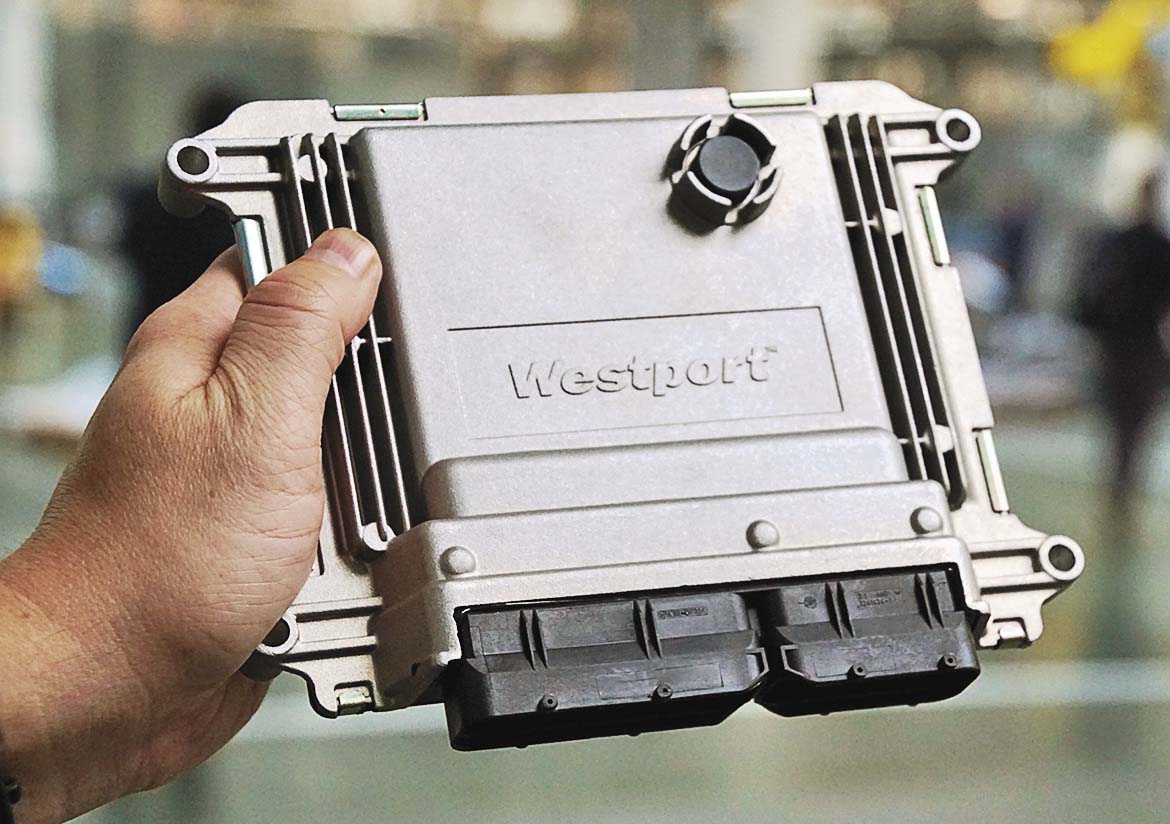

In their design is missing a number of parts, which enables the flow of fuel from diesel counterparts. To these are the atomizer, battery, pump, pipework and filters. Also changed the cylinder head, it cover, turbocharger, piston with rings, glass injector, bearings, sensors, control unit and wiring. Of course there are new elements that supply of gas fuel: filter, piping, throttle plate, injectors, spark plugs and the ignition module and etc. Gas motors are equipped with a set of desired sensors: camshaft position, crankshaft position, pressure and oil temperature, coolant temperature, on the issue is the valve position sensor EGR. In the intake system installed turbine and the intercooler. Controls the operation of the engine electronic control unit of Westport. In addition, the engines have undergone the process calibration.

In the fuel supply system of the gas engines found the use of a number of elements of foreign origin

In the fuel supply system has found application Nikki injectors, fuel filter, low pressure brand Parker, the fuel pressure regulator Emer, fuel filter, high pressure Westport. In the ignition system are the ignition coil Marshall and candle Bosch, which is to ensure same put all the sensors and throttle valve. The bears turbocharger Borg Warner brand, power steering pump and gear – ZF, valves and ear – Mahle, water and oil pumps – OMP, cylinder head cover with gasket – Dana, valve seals – Freudenberg.

Controls the operation of the engine electronic control unit of Westport

Engines YAMZ‑530 CNG easily integrated into a variety of freight, passenger, road‑building and agricultural machinery. The engines have a high export potential. The parameters of the gas engines YMZ‑530 correspond to the technical level of the best world analogues. The experimental samples passed the comprehensive tests in specialized test bench, "Autodiesel", and then proved to be reliable at the time of testing on trucks GAZ, Ural, buses PAZ, LIAZ and other models. The life of the engine depends on the modification is to 1 million km.

As noted by the President of "GAZ Group", Vadim Sorokin, transport equipment gas engines will significantly improve the efficiency and environmental safety of passenger and cargo transportation. The YAMZ‑530 CNG with the best world standards in the specific power, torque, vibro‑acoustic characteristics and fuel consumption. And through the work of the localization of components for our range of diesel and gas engines JAMZ‑530, which GAZ Group leads on the past two years, managed to keep the optimum cost of the engines, which will provide affordable prices for consumers of gas transport with engines YAMZ by compared with imported analogues.

On the"Avtodizel" is working on the creation of gas engines that meet Euro‑6. They will have capacity of 210 HP in YAMZ‑534 CNG and 350 HP in YAMZ‑536 CNG. Such engines, according to appear to be 2019 year. To this time the level of the Euro‑6 will satisfy and diesel engines YAMZ‑530. This will open the "Avtodizel" the markets of the European Union.

Prospective motors – advanced manufacturing

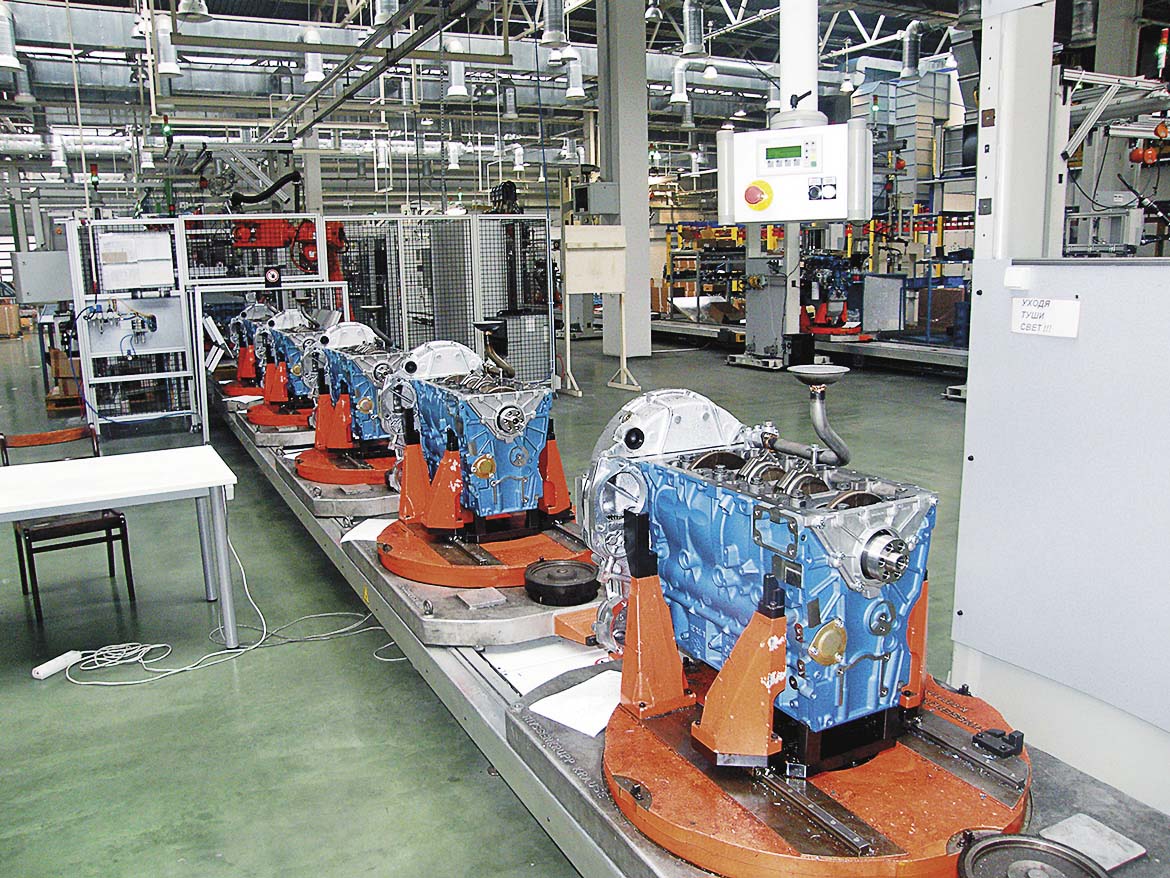

The production of new gas engines is conducted in a single process flow with diesel engines YAMZ‑530 production, which is one of the most modern venues in the engine in Europe. Plant a total area of 57 km2, with modern technology and engineering equipment, began work in 2012 year.

The production of new gas engines is carried out in a single process flow with diesel engines YMZ-530 is the most advanced production

The production is certified in accordance with the requirements of international system of ISO/TS 16949. The level of automation of the technological complex reaches 90%. Engineering infrastructure provides the implementation of the most stringent requirements for manufacturing environment purity, temperature, pressure, illumination, noise and vibration. The production capacity of gas and diesel engines YMZ‑530 is 20 thousand year is 40-50 thousand units. In the framework of the project formed a team of employees with significant potential for development, high educational and qualification level (higher education – 72%, possession of the skills and methods of the international system of ISO/TS 16949-100% of staff). The total investment in the plant construction and the development of a line of diesel and gas engines of the family YAMZ‑530 was about 11 billion rubles.

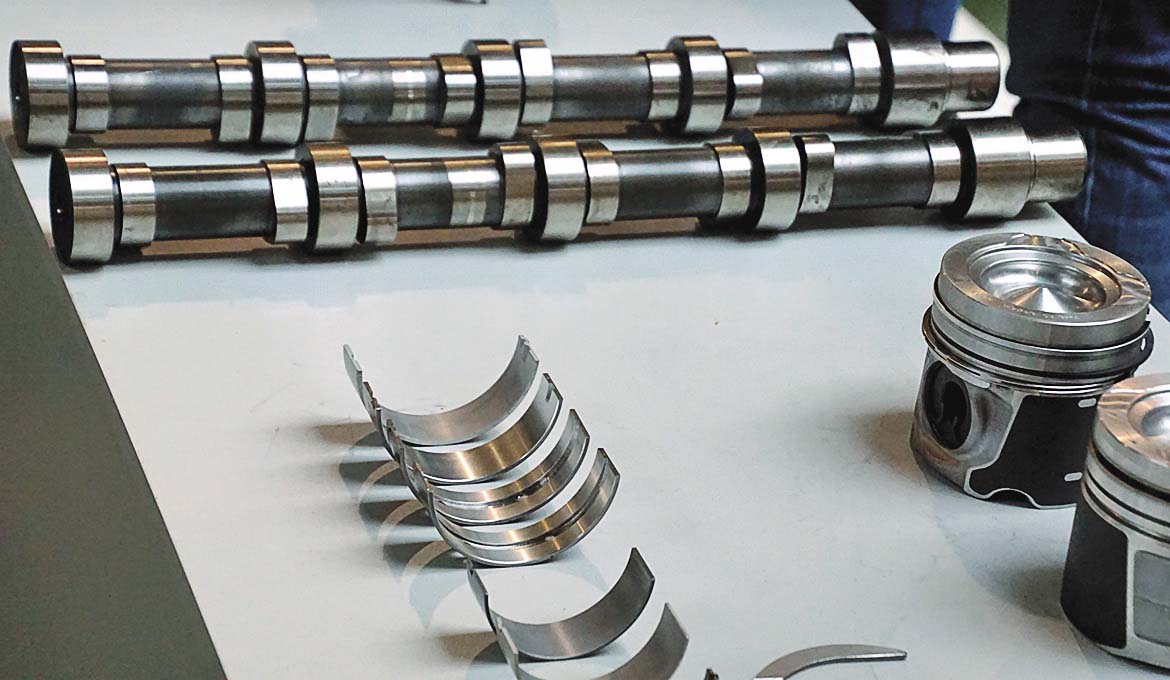

In project the organization of production of diesel and gas engines of the family YAMZ‑530 is the localization of components, in particular high-tech, with the location of production in the Russian enterprises. On today enterprises of "GAZ Group" and other Russian factories localized a number of components, previously produced in Europe, including casting cylinder block, forged crankshaft, turbocharger, camshaft and etc.

So it turns out that if 2016 years, the ratio of imported and domestic components in mid-size the engines were, respectively, 30% to 70%, then the end of the year of Russian components is already 85%. We can safely say that is one of the most effective projects of import substitution in the domestic engineering. As a result of the imminent reduction in the cost of production of engines on 25-30%. Localisation of parts for engines YMZ‑530 is not only allows you to provide a competitive cost of production with the preservation of quality on the world level, but also to reduce dependence of the economy of the enterprise and exchange rate fluctuations and simultaneously increase the volume of production on the enterprises of the Russian suppliers.

In the framework of the production of diesel and gas engines of the family YAMZ-530 is the localization of components

Frontiers of heavy class

Talking about the activities of "Autodiesel" cannot tell about the engines of the heavy class. The improvement of diesel engines YAMZ‑650. These in-line 6‑cylinder engines with dimension DxS=123х156 mm are available for the license of the French company Renault Trucks. When the working volume 11,12 L. capacity is 311, 361, 412 HP and maximum torque of 1215 to 1870 N·m at 1100-1400 min-1.

Modified turbo diesel YAMZ‑651 YMZ‑652-level Euro‑4, which is the brainchild of experts of "Autodiesel" and engineering firm Ricardo (UK), began the further development of the basic model YAMZ‑650. The power plant got the EGR system with particulate filter muffler‑catalytic Converter in the exhaust system of the type PM‑CAT, upgraded fuel system Common Rail, changed the cooling system and boost, modified the cylinder‑piston group. In depends on the minimum power specific fuel consumption: 190-194,5 g/kWh.

Diesel engine JAMZ-652 complies with Euro-4

The installation of more advanced fuel injection equipment with increased to 200 MPa pressure injection and SCR system allowed to develop and master the serial production of the model YAMZ‑653, complying with the requirements of Euro‑5 standard. Thus, the power increased to 422 HP and maximum torque – up 2000 N·m at 1100-1300 min-1. The resource reaches 1 million km. Since the technical reserves of the motor is limited version of the level of the Euro‑6 to create a plan. Your baton YAMZ‑650 in the near future will give the family of the next generation of engines JAMZ‑780, which includes a powerful high-speed diesel engines intended for installation on a serial promising models of commercial vehicles and military equipment. The new family is designed for installation on tractor, agricultural, water and military equipment. I must say that these in-line six-cylinder units working volume of 12.42 l has absorbed all the best that there domestic the global diesel technology. Most modern fuel injection system Common Rail, advanced control electronics and turbocharging, the cylinder block is high strength and other structural solutions will help to expand the boundaries of the power of 400 to 750 HP and in further to 1000 HP more. The maximum torque reaches 3000-3700 N·m.

Unification within the family will reach 70%. This cylinder – piston group, crank mechanism, head cover to cylinder block, elements of fuel injection equipment, turbocharging and electronic engine control unit (ECU). In the advantages of YAMZ‑780 it should be noted compliance with standards Euro‑5, and the future of Euro‑6, low fuel consumption in all range of working conditions and low cost of operation. However, maintainability is on top. To obtain objective information about the condition of the systems and assemblies of the engine in the standard configuration has diagnostic sensors and connectors. New for the weight and size figures are close to predecessor, YAMZ‑653, and therefore, can be placed on that same equipment. Production of the new collection, scheduled for 2018 G., will meet the demand for the power plant with a capacity of over 420 HP, which is now dominated by V‑shaped model.

In 2020 year will unfold serial production car variant of the model 780, the designation YAMZ‑770. Its power range is in the range from 370 to 550 HP

In the present time the largest volume of production comes from V‑shaped diesel engines dimension DxS=130х140 mm. the Collection combines heavy 6‑, 8‑ and 12‑cylinder units working volume of 11.15, and 14,86 22,3 l different environmental classes. Power turbo "sixes" YAMZ‑6565 (11,15 l) is 230-300 HP and the"eight" YAMZ‑6585 (14,86 l) is 330-420 HP enforcement of Euro 4 engines equipped with ECU, SCR system, and also fuel equipment Common Rail (with using the pump "CD‑40") increased to 180 MPa maximum injection pressure and multiphase flow of fuel. In addition to all of the revision was subjected to the cylinder block, cylinder head, flywheel, and its crankcase, intake manifold, in turn, the crankcase ventilation system is performed closed. Previous work has allowed simply go to produce motor variants motors V‑6 and V‑8 environmental class Euro‑5. Moreover, YAMZ‑6585 capacity was raised to 500 HP and a torque – up 2000 N·m this goal changed the timing, adjusted the fuel injection system, different turbo set up, modified oiling system, improved the cooling efficiency of the piston of modified construction. In the process of further upgrading the capacity of the YAMZ‑6585 will be increased to 530 HP Specific fuel consumption of both motors is advanced level – 194 g/kWh.

How can you not say that the manufacture of fuel equipment for these engines, ECU, software, electronically injectors with increased injection pressure has taken on the domestic enterprises.

In the lineup as first remain the engine line-up V‑6 and V‑8 environmental standard Euro‑3, Euro‑2, Euro‑1 and even Euro‑0. The models YAMZ‑6581, YAMZ‑7511, YAMZ‑236 and YAMZ‑238 power 150-420 HP are available as spare parts for previously released vehicles, used on road construction equipment, military machinery and St., where environmental requirements are not so strict. The production of V‑engines, also like model YMZ‑652, forcibly stop no one going to until the them there is a demand. And all same the proportion of V‑shaped 6‑ and 8‑cylinder engines in the General circulation is steadily declining. Already at the end of 2016 it will be less than half for the first time in all time of existence of "Autodiesel".

In the production program of the company can still issue the family a heavy V‑shaped 12‑cylinder diesel engines YAMZ‑240 working volume of 22.3 L. Units with direct fuel injection in beznadejnoi inflatable versions with a capacity of 300 to 500 HP meet Euro‑0. Complete production programme of heavy V‑shaped 12‑cylinder diesel engines, a working volume of 25.86 l and dimension DxS=140х140 mm.

Series motors YAMZ‑840 (Euro‑0 and Euro‑1) with a capacity of 650-800 HP, equipped with direct fuel injection, turbocharged with intermediate cooling, cylinder heads with four valves. Similar technical performance of the engines of YAMZ‑850, developing power 440-680 L.C. meet the Euro standard‑0. The power plant of both groups apply only to heavy mobile and other types of special equipment, including military.

In 2016 year "Autodiesel" plans to release 41,9 thousand engines, 35.6 thousand the year before. The mite in common cause will make a gas motors, the company expects to the end of December will release a 500 units. In Yaroslavl hope that growth will continue IV short term: in 2017 the company plans to make to 45.9 million, and in 2018 59,6 thousand engines. To do this, power on the production of YAMZ‑530, on some production areas today is already loaded up to the limit, will have to increase. In five years they should increase with the current 20-25 thousand 50 thousand units in a year.

Inseparable companions motors

Impressive and range of "Autodiesel" manual transmissions.

To a five-speed units are the basic model YAMZ‑2361, YMZ‑0905 YMZ‑1105, to six-speed – YMZ‑1406, to an eight – YAMZ‑2381 (together with Tutaev motor plant), nine - – YMZ‑239, YMZ‑2391, YMZ‑1809, YMZ‑1909.

In the process of upgrading 5‑ and 8‑speed samples acquired with a pneumatic booster transmission shift, the input shaft of larger diameter electronic speedometer gauge, a clutch housing, made in accordance with the requirements of the SAE, the hatch for mounting the amplifier off clutch pneumatic-hydraulic type.

At the same time mentioned 6‑ and 9‑speed models of the new generation besides all equipped with an electro-pneumatic control of various degrees of automation, the run lock the starter in gear, homenethelp, more power to 100 HP

Developed prospective transmission YAMZ‑330 with 14 steps. It a definite trump cards are: the dual planetary design with two bands, the divider and the synchronizers on all gears (except first and reverse). In addition, in the design of an embedded mechanism to install a remote actuator, electro-pneumatic switching and dual divider the ability to automatically lock the lower range of dual.

In the plans of "Autodiesel" – further improvement of the transmission and development of serial production of new models such as 5‑speed YAMZ‑1205 YAMZ‑Э1205, and also YAMZ‑1309 with 9‑speeds. Already in the following year, YAMZ‑1205 will be the affiliation of trucks MAZ and Ural, and YAMZ‑1309 – in 2019 year.

.

|

|

|