The Soviet industry in the years of the great Patriotic war

Soviet the automotive industry has contributed to the Victory over Nazi Germany less aircraft and tank

The role of road transport in the years of the great Patriotic war is difficult to overestimate. A huge volume of cargo equal to 625 million tons of freight that occurred often in combat conditions, day and night, in frost and thaw, says it yourself. And the courage of the drivers and their mass heroism on the front and in the rear, worthy of eternal memory and respect of posterity.

Memorial drivers, soldiers stands on Bryansk and every passing driver considers it its duty signal horn to pay tribute to the heroic drivers front pores

The industrialization conducted in the USSR in 30-e years, establishing a large automobile manufacturing in the bitter Moscow in a record of the historic period ensured the national economy and army trucks, to form a new industry – road transport and also to significantly raise the level of motorization of the army. In 1937, for the production of trucks (180 thousand per year) our country has entered the first in Europe, ahead of countries such as England, France and Germany. It was planned that already in 1942 the total production of vehicles in the USSR will reach 400 thousand units, and starting at this year, will start production of new generation models, much more productive and economical.

The fleet of the red army, yeah and across the country before the war was very consistent lorry "Jeep", trachenko male, Yes patience "Yaroslavl bear"

The war destroyed those plans. Four plants of the automotive industry of the USSR (Moscow ZIS and KIM, GAZ and GAS Yaroslavl yaz) had to be reoriented for the war effort, including the development of new military products.

Moscow plant them. Stalin produced 3-ton trucks ZIS-5, 4-ton, 3-axle ZIS-6, gas ZIS-30 and ZIS gas generator-21. Four-wheel drive 2-axle ZIS-32 only started to explore more modern models were tested and the stage of preparation to production.

AWD ZIS-32 made at least two hundred (188 units) and they all remained in "white the fields under the Moscow"

When the enemy came to the gates of the city was made the decision to stop automobile production and evacuation equipment and employees in the town Miass, Ulyanovsk, Shadrinsk, Chelyabinsk, Troitsk and Irbit.

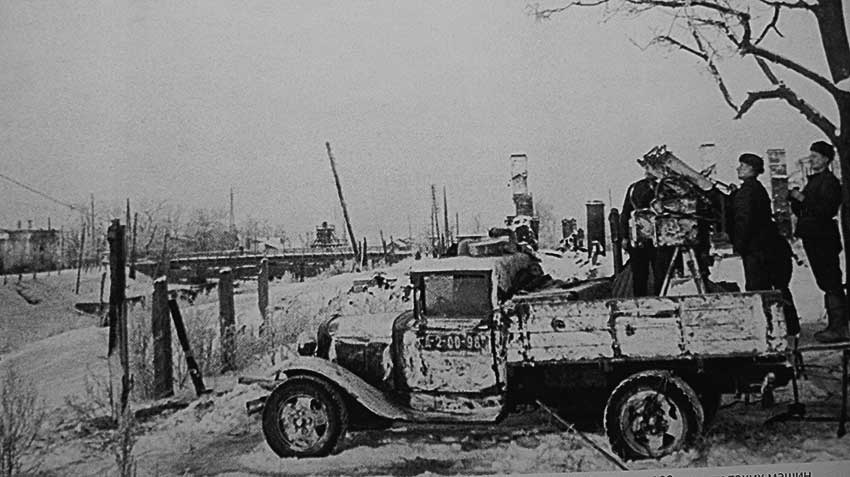

Anti-aircraft gun 4M (from chetvertnykh Maxim machine guns) in the back of the lorry GAZ-MM

Just the rear was sent to 12 800 units of equipment for 7708 wagons and platforms. With the factory were evacuated 6907 workers, technical workers and employees and with their family members – 14 166 people. Footage Moscow ZIS became the basis of new groups of plants on East of the USSR. In the disposal of the Director of the Moscow ZIS I. A. Likhachev was a special plane that runs between the factories of the Urals, the Volga region and Moscow.

Crossing, crossing – left Bank, right Bank

And in Moscow ZIS given the task to start production of mortars, mines, shells and other military products, including submachine guns Shpagina. Of the remaining touched parts in the end of 1941, the year was able to collect several hundred "of trentodoc" ZIS-5.

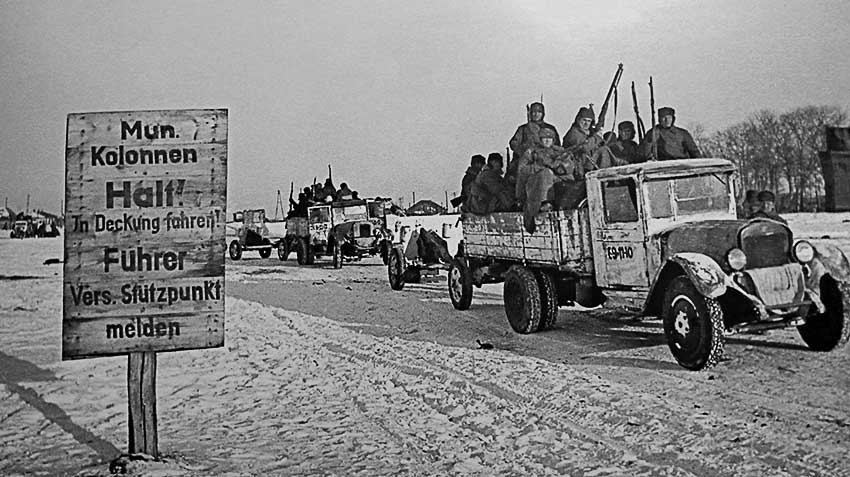

Pre-war three-ton ZIS-5 go to counteroffensive at Moscow in winter 1941

Unlike the ZIS GAZ automaker producing for army main "lorry" GAZ-MM and treneski GAZ-AAA, evacuation is not subject.

Refugees wander from his simple belongings in the rear, and the convoy of trucks (closes chesticles GAZ-AAA) understands where the front line

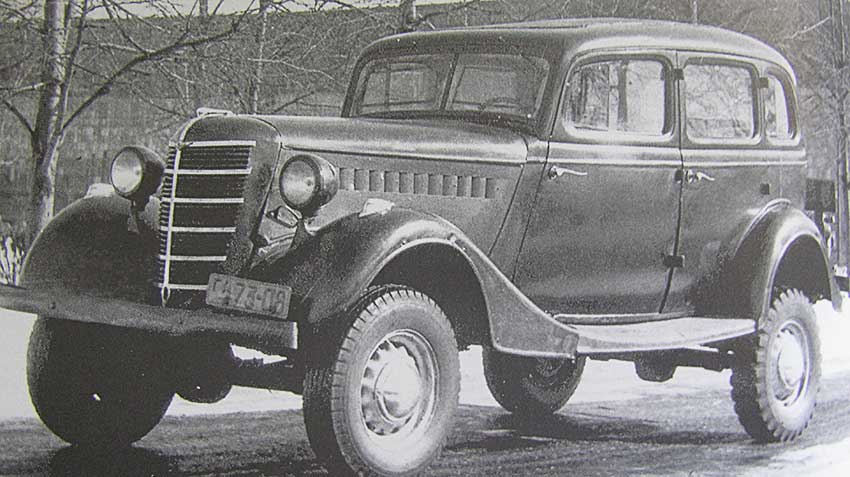

GAZ-M1 "Emka" was the main staff car of the red army in the beginning of the war

His task was to maximize production volumes and parallel to develop military equipment, and also weapons and ammunition.

Back in the spring of 1941, the year the Gorky automobile plant was developed reconnaissance vehicle R1

Later he became the legendary GAZ-64 and GAZ-67, in a number of indicators superior to the American counterparts, firms Bantam and Willys. Design of the GAZ-64 was developed by a team headed by V. A. Grachev, for extremely short time – 51 days.

Early "Ivan Willis" GAZ-64 1941-42.

Light armored car BA-64

GAZ-67 light confidently out EP instead of horses

"Bobby" GAZ-67B (1944-1953 gg.) entered with our troops in Berlin

And the main jeep of the great Patriotic war was the lend-lease Willys MB

Along with half-track GAZ-60, triaxial sanitary bus GAZ-05-193 and chassis armored cars BA-10 to the front received very well constructed armored cars BA-64, which helped in military business intelligence and also played the role of the commander's car.

All-wheel drive sedan GAZ-61-73 (by the way, the first such in the world), produced in 1941-1945 relied only to the higher command of the red army

The third factory, which produced in the USSR, trucks, Yaroslavl yaz to the beginning of the war was a rebirth. Beginning of the reconstruction was to increase its capacity up to 10 thousand cars in a year. It was planned to issue 8-, 10 - and 12-ton models with two-stroke diesel engines ranging from 110 to 160 HP, which would be released the plant itself. All this is not allowed to organize large-scale deliveries of cars in the Red Army. Among the defense products developed Autom, tracked artillery tractor I-12, weapons, and ammunition.

In June 1941, the year the Moscow plant them. KIM was a hard work on the production of subcompact KIM 10-52. For needs of red Army, the factory produced gear box heavy motorcycle M-72, but already July, issue of pre-war production was discontinued. Of the remaining reserve components have been collected a number of cars KIM-10 simplified body, unofficially called "Tachanka".

Heavy scribbles for the blue handkerchief that was on the shoulders of the road

But the main product of the enterprise of steel rockets caliber 132 mm multiple rocket launchers BM-13. In October, the plant was evacuated to the Sverdlovsk, where, together with a Tank factory No. 37 1 December started production of light tanks T-60 and shells air guns. In the shops of the Moscow plant in during the war years was deployed to repair the tank engines-2, and then issue repair parts to the cars coming in the lend-lease act.

But the steering wheel is not threw driver

Among the evacuees with the ZIS production Ulyanovsk automobile plant became the leading, although his shop is located in unsuitable for production premises of single-storey warehouses of the General administration of customs. With on may 1, 1942 years, the UAZ started the Assembly of trucks ZIS-5 of the units node, brought from Moscow. To end of the year managed to gather 1893 car, sent to the front. The plant mastered the manufacturing of steering, prop shaft, front axle, rear axle, frame, cab and platform. Production of engines and gearboxes instructed the branch of the VMS to Miass. Other plants of the group ZIS did carburetors, radiators, forgings, stampings, body parts and frame.

Permeability of domestic trucks on the front were often accompanied by muscular force fighters

During the war the ZIS-5 and GAZ-MM were produced in a simplified form. This allowed to speed up their production and to save scarce materials. Instead of a complicated shape formed of the wings of the machine were supplied with welded l-shaped. Front bumper and right headlight was missing. Brakes were installed only on the rear wheels. From the body was only opening the tailgate.

On the truck GAZ-MM 1942 years mounted a simplified cockpit with canvas top and a canvas canopy instead of doors

In 1943 it was replaced by a wooden locked cabin with a roof covered with a tarpaulin. ZIS-5 military time, to get the index ZIS-5V, was also a wooden cabin with top of the leatherette, stretched on the rack.

The military version of ZIS-5V 1944 after years have already received the two lights and side drop side

Simple design, maintainable and low fuel quality and "polutorka" GAZ-MM, and "techtone" ZIS-5 had a fairly high permeability when driving dirt roads and honestly performed their duty, sometimes led by inexperienced men, the drivers, recently received law. There are many cases when the enemy Nazi units tried to use captured Soviet trucks, better adapted to the realities of military service in the USSR, abandoning their vehicles and shifting burden of the body of the Abstracts and Gases.

Sanitary car ZIS-44 was produced from 1942

On the difficulties of army service military drivers says a lot. It is impossible not to recall just about the"Road of life", organized by the ice of lake Ladoga for the evacuation of citizens and delivery the besieged Leningrad products and ammunition. In the winter of 1941 – 1942 on ice road had about 4 thousand cars (mostly GAZ-MM and smaller number, ZIS-5), led by the courageous drivers. Their Titanic work, the writer survived the blockade of Vera Inber in his "Leningrad diary" noted as "Holy work".

In the fierce cold of the drivers as in the Patriotic war of 1812 year, saved a loyal friend fire

We should also pay tribute to the lorry GAZ-AA MM, which was much easier than three-ton ZIS-5, and was able to walk for more thin ice, opening and closing "navigation", not mention that rarely failed under the ice. In critical days, when the Leningrad remained a supply of bread for 3-4 days, went to the bottom of lake Ladoga lorry with flour and nadejalsja to the city of three revolutions, it was possible to lift on the help of simple mechanisms embodied in wooden rafts around the hole in the ice. And it is hard to imagine the physical complexity of such operations on severe cold under the bombing, but truly strategic goods of these trucks, which is then dried and baked from his precious bread, began saving for hundreds of thousands of Leningrad siege survivors, he managed to bravely endure all the horrors of a deadly famine. "Road of life" in the winter of 1941/42 year lasted 142 days from November 41-go on April, ' 42. For this time the car was taken in the city of Lenin 361 thousand tons of cargoes, primarily food (262 thousand tons), and evacuated more than 550 thousand people. Just 1941-1943 on Life in St. Petersburg carried more than 1.6 million tons of cargo and evacuated about one million Leningrad residents, in the main, children.

When the ice has passed, the truck was on him closer than 100 meters from other and the doors open to have time to jump out of the cockpit when the car started to go under water

In January 1942 year, the State Defense Committee adopted a decision on the recovery of automobile production on the Moscow automobile plant. Proposed to expand the production of trucks ZIS-5, not disturbing growth of defense products, and to produce new models half-track vehicle-ATV ZIS-42 intended for towing artillery pieces. With this purpose we had to return in Moscow on the East part of the equipment, mount it and to restore communication, destroyed at the evacuation of the plant and the dismantling of its productive capacity. Challenge managed to solve to June 1942 when the gates of ZIS again began to leave "three-ton" is very right front.

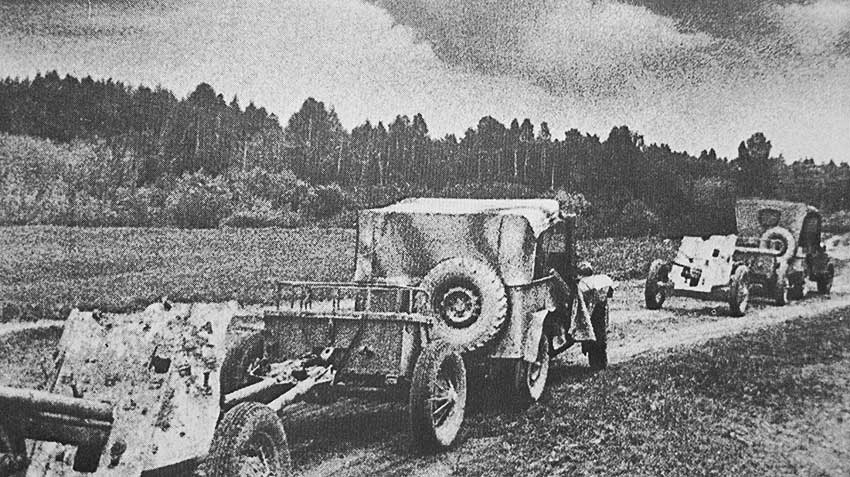

Exactly half-track tractors ZIS-42 provided along with tractor mobility of the red army artillery during the autumn and spring thaw

Before the war, the ZIS with NACHI studied the possibilities of creating a half-track vehicles up to a batch of vehicles ZIS-22, but to their large-scale production is not reached the war intervened.

With the end of Soviet-Finnish war and up to the mid 1940 years of ZIS delivered to the front about 4.5 thousand all-terrain vehicles ZIS-33

The vehicle was a standard ZIS-5 with a lightweight primitive tracked vehicle that can easily be mounted and easily dismantled in case of need. The car was bad, very heavy, unreliable and power hungry. A similar idea has been buried, now the ZIS-42 was supposed to be a rehabilitation design, which the less has been used the maximum number of serial units and nodes ZIS-5V.

The most advanced Soviet semi-tracked truck ZIS-42M sample 1944 years (photo's only the country authentic restored copy)

In September 1942 years, on the eve of winter, the first ZIS-42 was received on the front. It is known that they fought under Stalingrad; and took them off production 1944, having made 6372 car.

Column in the composition lolitushka penetranter, the Soviet half-track tractors and conventional trucks prepaired in the Kursk bulge

In the second quarter of 1942 year the Moscow car factory ZIS began assembling imported trucks from the sets, obtained according to lend-lease. In the Studebaker US6, on which was mounted rocket launchers "Katyusha", but was and other model truck chassis brands Dodge, Chevrolet, GMC and so on. Similar work was carried out on the Gorky automobile plant. By the way, more than a quarter of all lendlizovskie chassis immediately went under the complete set of weapons (mainly rocket launchers "Katyusha"), so that the contribution to the Victory of imported vehicles does not underestimate.

The legendary "Katyusha" (BM-13N) on the American Studebaker US6 chassis

As it became known, in 1941, the Nazi leadership set the task of destruction of the Gorky automobile plant, which significantly could reduce the military-economic potential of the USSR. (Except vehicles in Gaza was organized and manufacture of light tanks). The goal was achieved in night 4 July 5, 1943 years, when Nazi planes flew 25 raids on the GAS. The destruction suffered 90% of the shops, Sotsgorod, roads and railway tracks. It seemed that to restore the factory impossible. But the State Committee of Defence has set the task to restore the factory 100 days. To help gorkovchan profit builders and performance of Moscow, Siberia, and the Urals. In the work that went on throughout the day, was attended by 33 thousand people working at 18 – 19 hours in a day. 28 Oct 1943 years of located in Moscow was sent a report on completion of Gas recovery. Over 100 days builders have mounted 3300 tons of metal, put 3 million bricks, paved 142 km of pipes, wires and cables, glazed 105 thousand m2 of window openings, constructed 6 thousand m2 of living area. And again front and the rear went the Gorky car.

Light tank T-60 also played a role in the front, though not so outstanding as the legendary T-34

Light tanks T-60 GAS produced EN masse

In 1943, the state Committee of Defense adopted a decision on the transfer of the production of the ZIS-5V in Miass. In relations with the equipment of the shops of the main conveyor, chassis, mechanical Assembly, and several others were sent to the Urals. 8 July 1944 Miass factory became the Ural automobile plant assembled the first truck.

On the streets of Vienna

In 1944, on the outskirts of Minsk began the construction of the Assembly plant. Gorky plant helped in equipping it with equipment of Assembly line, shipped tool. In 1944 year the plant began the Assembly process imported trucks of lend-lease sets. In the future, this plant became the Minsk automobile mastered the models developed Autom.

So we in Berlin road!

Just the war Soviet factories gave the front 265,6 thousand cars, and of lend-lease sets – collected about 340 thousand (all deliveries according to lend-lease amounted to 427,5 thousand).

Reliable and durable pickup truck "Dodge ¾ ton" (Dodge WC-51) was the most reliable assistant for the Russian roads

.

|

|

|