Progress in Nizhny Novgorod – from sledgehammers to Andong

From manual labor at all operations to a deserted automated welding lines.

For 85 years their work history Gorky automobile plant has passed the way

from classic conveyor assemblies ferdowski to the modern system of the Toyota Product System with cord Andon. From manual labor for all operations to unpopulated automatic welding lines.

Today AZ GAS on its 650 acres are United not only in automotive power with a full production cycle: welding, painting and Assembly, and numerous automotive components, including metallurgical, forging, tool and frame and stamping, in addition, there is production of valves, wheels and steering, in a separate building is manufacturing ferrous castings, automobile units plant, as well as its own engineering centre. Investments in development and modernization of the technological chain and the updating of the model range was about $1 billion since 2011 to create a Park of automotive components, seeks to further import substitution. Manufacturers are interested not only in related supply inside the GAZ Group, but also in expanding the range and supply on the open market, which improves production profitability.

Introduction in 2003, the revolutionary production system GAS developed on the basis of the principles of the Toyota Product System has allowed over the past decade, four times to increase productivity, reduce costs and increase the profitability of the business. So instead of 250 people on the main line there are only 90 people who gather more and better than the previous workers, the length of the conveyor area is reduced to 40 meters. The famous cord emergency stop conveyor "Andong" is also available here and, if the employee is unable to cope with a certain problem, he pulls a cord, after which the conveyor is stopped and within two minutes he can eliminate the problem itself, and then connects the senior master, well, if the delay exceeds 20 minutes (at present something incredible), connects himself chief engineer of the plant. Anyway, the quality is now on Gas in no less esteem than before was the number.

Plant tour for journalists allowed to directly look at the most important production, though, due to the shortage of time was able to visit only the most important of them.

Assembly plant

Start with Assembly shop as the most iconic for any automobile. The main conveyor is in the shop. Final Assembly of the chassis and tsmf is on four threads, one of which is given to the Assembly of tsmf Mercedes-Benz Sprinter Classic (here we are asked not to remove, since the rights belong to Daimler AG). On one leg of the conveyor are srednetonnazhnye (LDT) as an old (GAZ-33098 and GAZ-33088 "Sadko" and GAZ-33086-74 "Countryman"), and a new "Lawn NEXT". In addition, there are "intermediate" conveyor Assembly line directly to the cabin.

Virtually the entire range of srednetonnazhnye now equipped with diesel engines or gas series motors YMZ-53443-10 Euro class 5 (see CH1).

On the next thread coming on-Board and chassis "GAZelle" series "BUSINESS" and "NEXT". Model tsmf both series are collected on a separate leg of the conveyor.

Most of the "Gazelles" equipped with the gasoline engines EvoTech, but there are Cummins diesel engines ISF2.8L, mainly on NEXTах. The ratio between the "side" series the "BUSINESS" and NEXT

for 2017 has changed from 60:40 to 40:60, and next year it will be 20:80. Tsmf at a ratio of about 55:45.

About 20% of the trucks on the Assembly line equipped with Gas-cylinder equipment.

The dimension of the LPG cylinders under the most diverse.

Bridges and exhaust system the easiest to install inverted "on the back" frame.

Cabin of paint shops are transported to the Assembly line of cabs in pairs.

Cabin module for Ural NEXT after the welding and painting is Assembly line for cabs on the Gas and then sent to the Miass in the Ural.

The chassis is complete for the NEXT bus Vector with a larger base and the location of the driver's seat over the front axle.

In the area of Audit with a special fluorescent lighting is Troubleshooting quality paint coating and other defects, after which the cars go 80 km run on the factory test site and sent to customers.

The body welding shop tsmf

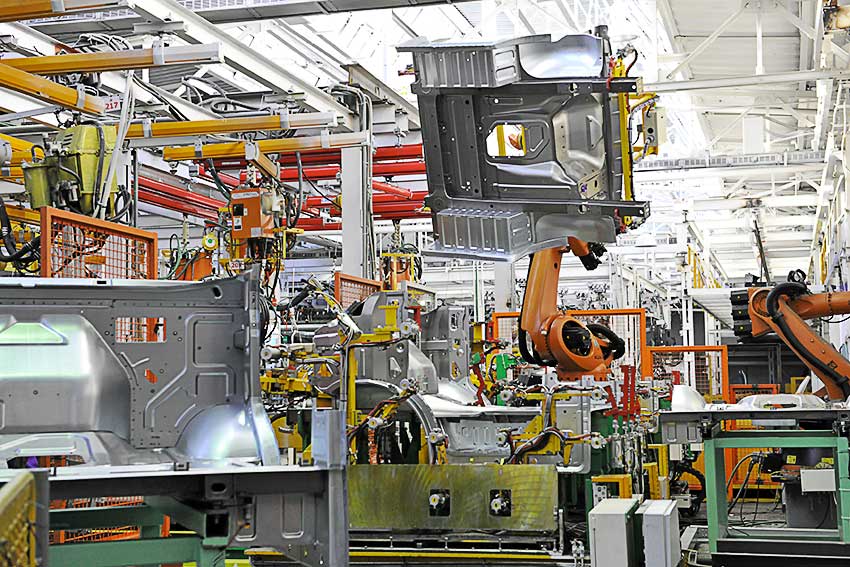

In the body welding shop vans and minibuses "GAZelle NEXT in automatic welding lines work 98 Japanese Fanuc robots, and the capacity of the most powerful robot up to 700 kg.

The robots do on the back of a van "GAZelle NEXT" 6000 spot welds, the maximum deviation at each point – not more than 0.2 mm.

Intelligent control system continuously monitors all the main welding parameters: amperage, and the force and time of compression welding gun and, if necessary, makes adjustments instantly. The maximum annual capacity of the complex is up to 50 000 bodies of tsmf in a year.

Welding quality is checked in the final according to set parameters of a body on a coordinate measuring machine.

Welding shop truck cabs

Although directly visit the welding shop truck cabs was given, not to mention the one, without exaggeration, a landmark production of "GAZ Group" is impossible. The cabin doing here

as for the local series of "BUSINESS GAZelle", "GAZelle NEXT", "Gazon NEXT", and operator's cab.

for the Miass Ural NEXT 8 types of cabins of various models and modifications are welding on a single production line.

Welding line are automated. Even with the installation of the base of the cab to the line electronics determines what kind of model and, consequently, changes the welding program. Hence, errors associated with human error, simply eliminated. Welding at the line of cabs is carried out 100 robots German manufacturer Kuka, who has 85 % of the operations. Precision movement "tentacles" of the robots is calculated with an accuracy of 1 mm.

Painting complex

In the paint shop, with equipment firms of Eisenmann is the cars of "GAZelle NEXT", "Gazon NEXT" and Mercedes-Benz Sprinter. It was interesting to compare the scale galvanizing have MB Sprinter Classic and "GAZelle NEXT".

On domestic models galvanized the entire body to the roof and a significant amount of the most prone to corrosion parts replaced by plastic elements.

The most modern in Russia painting complex with 13 different stages of cleaning, washing

and priming of surfaces prior to painting provides high quality surface preparation, priming and application of paint. It includes 22 air-conditioning system, in the end, allowing to achieve the degree of purification of air to 1 micron.

Inside the working area created by the increased air pressure which "blows" from paint cameras, even the smallest particles of dust.

Every body is cataphoretic priming in a special bath with full immersion.

The result of electrolytic treatment forms a protective coating, which more than

15 time increases resistance of metal to corrosion.

Sectioniii robots French company Sames provide an automated painting internal and external cavities. The output from the workshop is the examination body and compliance of the quality of the color reference samples.

Manually coloring only complicated the internal surfaces of the body. The introduction here of robots is still not economically feasible.

Frame and stamping manufacturing

In the press shop produces parts of the bodies all-metal vans

and vans series "GAZelle NEXT" and Mercedes-Benz Sprinter Classic.

Automated line of forming a class "A" is equipped with a multifunction six-axis Kuka robots and presses with die tooling LG. Line ensure maximum precision in the manufacture of parts and high performance. It produces large parts, including the front panel, side panels, base, sliding

and hinged doors.

The main part of the pressed panels are produced on a Japanese automatic lines Komatsu and part of the perimeter of the Gas plant dies and molds. Mathematical modelling, development of the technology and design of dies made by the specialists of Gas in conjunction with one of the world leaders in the field of engineering manufacturing tooling company V-EnS, a subsidiary of LG Corporation. The shop is equipped with 7 presses

with a force of 800 tons. The line can produce 6-8 parts per minute, and the total weight of die tooling for the production models of the NEXT family is 9900 tons.

The joint engineering centre of "GAZ Group"

Such an industrial giant as "GAZ Group" has established and the largest Russian engineering complex, which provides a full cycle of works on creation of the car: develop the concept, style, planning, prototyping, modeling

and tests, the formation of production processes, engineering, certification. The center was created

on the basis of engineering services of Gas and unifies the design of service enterprises "GAZ Group".

The Commonwealth worked with him and the factory racing team participating in rally-raids, for example, "silk road".

Training and development

Of course, to work on the most modern equipment and highly skilled personnel. So, to master modern production technologies

and professional development of workers at the Gorky automobile plant established a Corporate University, which has over 400 unique training programs for professional development as managers and professionals, and working for the most popular specialties.

Joint production of components

We also visited the joint production of BOSAL-GAZ, engaged in the production of exhaust systems, including catalytic converters. SP makes products not only for the range of GAS, but the company Volkswagen, and latest quite happy with the quality

and continues to expand the range of localized products. With the transition to the standard Euro-5 SP GAS-mastering BOSAL exhaust system in stainless steel.

A machine for rolling enclosures silencers.

Pipe bending machine

Stand on the control Provenge geometry of the exhaust system

In the laboratory, the SP checks the quality of the filler of the catalytic Converter.

The stand for check of working qualities of Converter.

Slogans in support of quality are as impressive as the production itself.

This item SP GAS-BOSAL started its activities in late 2011.

|

|

|