MAN rushed to the widespread introduction of platooning

18.07.2019

MAN Truck & Bus has successfully completed a pilot project of platooning DB Schenker

MAN Truck & Bus reported that its pilot project with a logistics company DB Schenker and the University of applied Sciences. of Fresenius, has completed successfully.

The main result of the world's first practical tests of semi-detached columns of the main trains (system platooning) in a real logistic trips carried out by the project participants in Berlin, was the confirmation of safety, reliability and technological small-scale mining operations this technology for use on German motorways for convenient solutions to everyday logistics problems.

In the framework of the research project EDDI, the financing of which the Federal Ministry of transport was allocated to 1.86 million and digital infrastructure, professional drivers on two trains on a virtual "electronic coupling" made within seven months of transport on the pilot section of the A9 motorway between branches of the logistics company DB Schenker in Nuremberg and Munich. Platonycheva convoy dashed about 35 000 test kilometers with maintaining a distance between vehicles from 15 to 21 meters, while the drivers appreciated the driving comfort trains and a General sense of security. In operational trials even managed to reduce fuel consumption.

In the opinion of the partners of the project semi-Autonomous convoy of road trains allows more efficient use of the space on highways that have a positive impact on traffic flows and improving road safety.

The Minister of transport and digital infrastructure of Germany, Andreas Scheuer (Andreas Scheuer) said: "Mobility of the future is inextricably linked with the automation and network connectivity. It in fully also applies to the logistics industry. So I fully support the implementation in industry of such technologies as platooning. We strive to make logistics processes – from loading areas to the client more safe, effective and environmentally friendly. At this the drivers of the trucks managed to take the lead modern experts in logistics. This opens up for the profession (truck drivers, of which there are today in Germany do not have more than 30 thousand – ed.) new perspectives on the future!".

Us$: system platooning can be used in 40% off all ground transportation

DB Schenker considers that the columns of the mainline trains can be widely used in logistical networks. Member of the management Board of DB Schenker AG in Finance, freight transportation and logistics Alexander doll said: "We looked at our European transport network and can confidently say that about 40% of all freight can be using a system of platooning". However, this requires additional testing and appropriate regulatory framework. Win clients: "the use of the main trains in the column increases the safety and efficiency of our vehicles."

Installed in MAN trucks, the automated system worked smoothly in 98% of cases. The driver had to intervene in the system only once per 2,000 kilometers, i.e. much less than expected. In addition, the pilot test was able to reduce fuel consumption by 3-4 %.

Chairman of the Board of MAN Truck & Bus SE Joachim Drees said: "We have proven platooning can make a meaningful contribution in reducing fuel consumption and CO2 emissions. First of all, we are pleased to note that the system operates reliably and contributes to increasing safety on the roads. Thus, platooning is the next step in the development of automated driving".

University: drivers feel confident

The University of applied Sciences. Fresenius investigated the psychosocial and neurophysiological effects of technology platooning drivers. Tests in real conditions have helped to partly change the critical attitude of drivers to the system. "The General feeling of safety and confidence of drivers to the technology included in the assessment of specific driving situations.

Professor Dr. Sabine hammer from the Institute for integrated health studies at the University. Fresenius said: "In each of the truck drivers kept control of the movement. Unpleasant, but not critical in the sense of drivers have experienced as a result of interaction with the vehicles of other traffic participants. "Thanks to the rapid response system the preferred distance between the trucks do not exceed today 10-15 meters," – said hammer.

Professor Dr. Christian Haas, Director of the Institute for comprehensive studies of health said: "the Results of electroencephalography (EEG) indicate the lack of systematic differences between trips on conventional trucks and in part manned the column from the point of view neurophysiological load on the drivers, namely the degree of concentration or fatigue".

For the implementation system on the international level, the researchers recommend further studies with longer stages of the movement of the convoy.

Cooperation partners are convinced of the high potential of the system of platooning due to further improvement of technology. In addition, platooning will contribute to the creation of new business models in logistics based on digital technologies.

the Principle of platooning

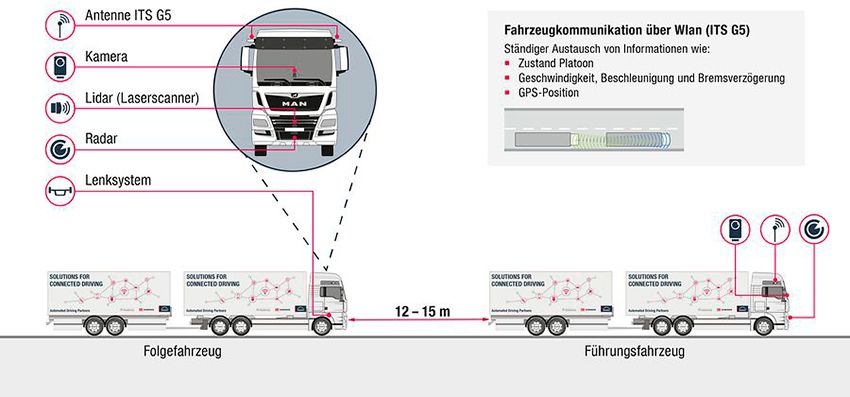

Platooning is a semi-Autonomous convoy, consisting of at least two trucks traveling on the highways at a short distance by means of technical management systems and the assisting of driver assistance systems. All vehicles in the convoy of the United electronic "coupling", through which communication occurs between them. Lead car sets the speed and direction of movement.

.

|

|

|