Gorky automobile plant turned 85!

Over 85 years in Gorky the plant produced more than 18 million cars.

Part 1 – History and modernity.

For 85 years, the Gorky automobile plant has produced more than 18 million cars. Eighty-five – age more than respectable, and for the company very solid, but our hero of the day quite fresh and active. Today the company is part of the automobile holding "GAZ Group", the main shareholder of which is the machine building holding "Russian machines", in turn, part of industrial group "Basic element". "GAZ group" includes 13 plants in 8 regions of Russia, as well as Assembly production in Kazakhstan and Turkey. Directly on AZ GAS today employs over 20 thousand people, and the Group employed 42 000 employees and another 400 000 jobs created in related industries.

If you look at plant height (from the factory brand of the hotel "Wave"), the area size of 600 hectares, is located on the left Bank of the Oka river, is impressive. However, the real modern production, together with the SP actually is not the entire area. Thanks to modern technology and know-how of organization of production, the plant is easy to cope

with the increased production load in much less space and with far fewer personnel.

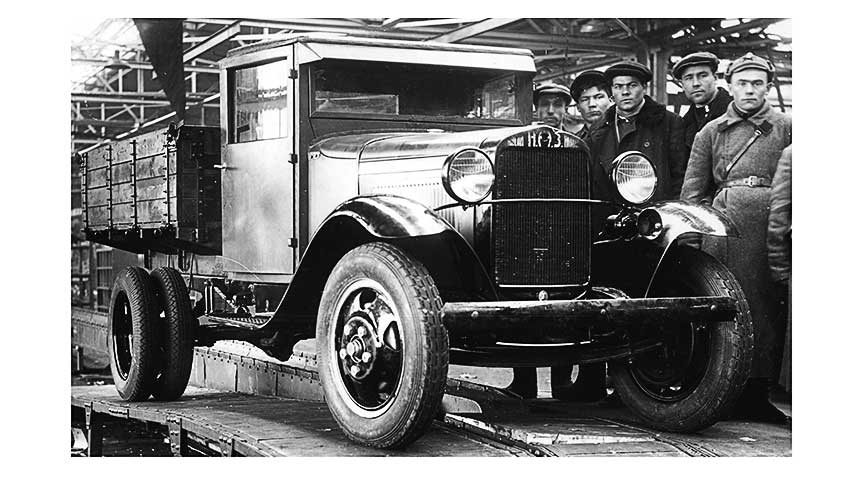

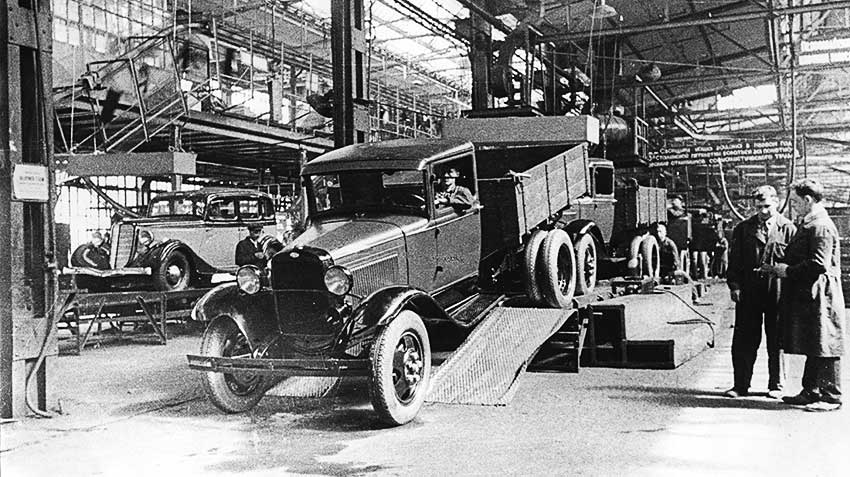

The plant was founded as the Nizhny Novgorod automobile plant in 1930 in the suburbs of Nizhny Novgorod in the village of Kanavino. As one of the impact of the first Five companies was put into operation after 18 months – January 1, 1932. However, full-scale production of trucks and especially passenger cars managed to establish only much later, when the town was renamed

in honor of the proletarian writer Maxim Gorky, and the plant became the State factory named Molotov (Yes, until 1957 GAS was just ZIM-Ohm in honor of Stalin's iron Commissar)

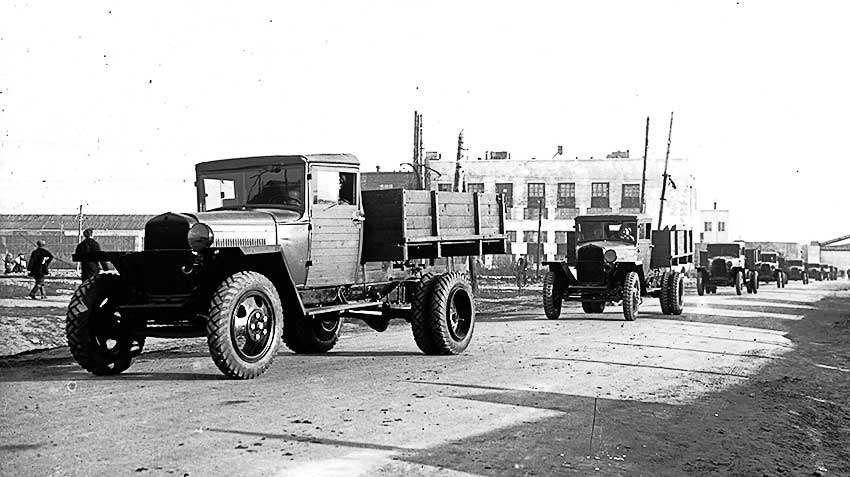

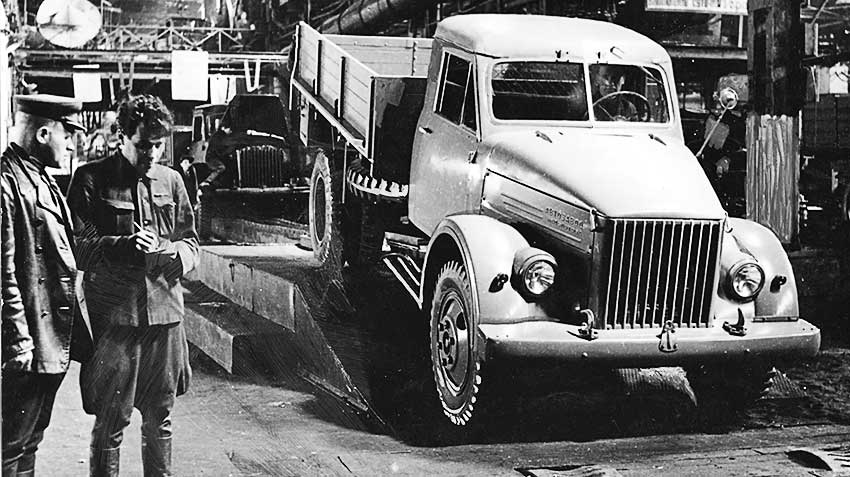

as Gorky automobile plant was a result of Khrushchev's policy of de-Stalinization after the capital ZIS-ZIL). And yet it is a fact that such rates of construction of such a large-scale enterprise in the global car industry in those years did not know. The plant was built with technical assistance of a number of American companies, primarily Ford Motor Co. In principle, a prominent American industrialist Henry Ford looked to Russia in the early 1920s, quite reasonably assuming that when the former Empire will be peace after a grueling First World and Civil wars, and the Russian automotive market will become one of the largest in the world. Actually what happened, but only in 1930 with the commissioning of the Nizhny Novgorod automobile giant with a capacity of over 100 000 vehicles per year. It is unpretentious lorry ГА3-AA (later GAZ-MM) was transplanted to a completely animal-drawn country on wheels, gave a reliable transport and support the army and the national economy, he worked on impact of the construction of the first five, and he bore the brunt of the great Patriotic war.

The first generation trucks (GAZ-AA/MM) produced nearly a million, although, together with several branches, including the capital, KIM. During the great Patriotic war was made 138,6 thousand of trucks, and a significant part of them in the gas version GAS 42, who worked on wood chocks. Completed production of the first generation Gorky trucks only in 1950. By the way, in addition to the basic model, it includes 2-ton chesticles (treneska) GAZ-AAA with a 6x4 (1934-1943 years), based on which, in the 1930s – early 1940s, it was released a solid number of armored vehicles (approx. 10 thousand BA-6 and BA-10/10M).

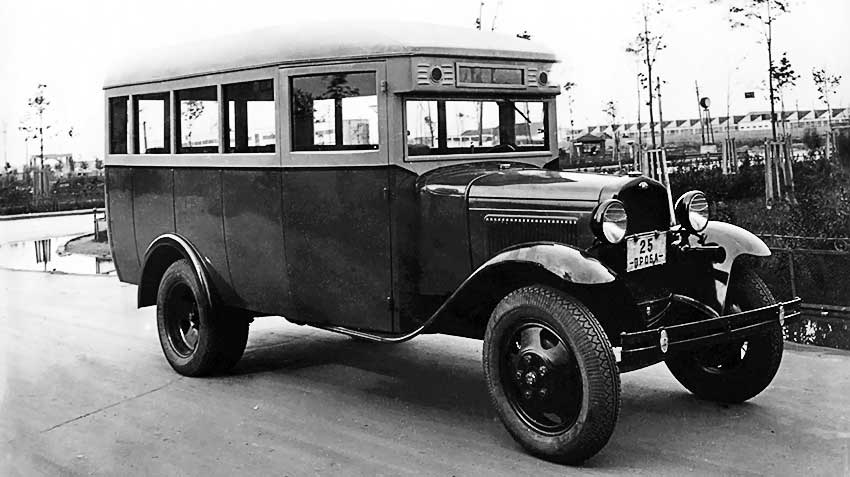

In addition, bus service in the country was largely started because of the mass model of the bus GAZ-03-30 (1933-1950), was built on the basis of the lorry and let loose on a branch of GSA (formerly plant "the Whistle of October", where in 1930 he started the first "Ford-AA" from imported parts).

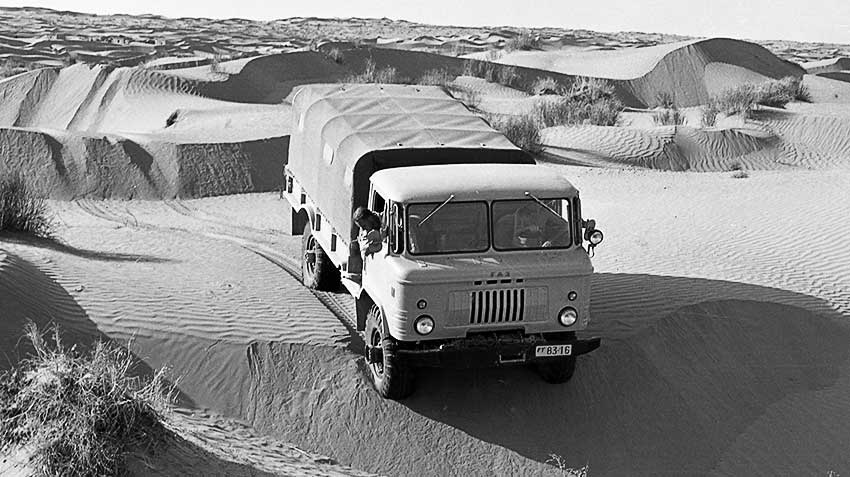

The second generation trucks – postwar a 2.5 ton GAZ-51 (4x2) and 2-ton GAZ-63 (4x4), translated as before the war (so even radnoy "six" GAS-11 on the basis of American motor Dodge D5 was able to learn more in 1940), went into production in 1946, and, without stopping production. Truck GAZ-51, first, because of the shortage of metal as the lorry was manufactured with a metal cab and only after the modernization in 1955 (GAZ-51A) received all-metal cabin and became one of the most popular trucks not only in the USSR (over 3.48 million units), but also in the world, and was even produced under licence in Poland, China and North Korea.

This generation is reliable, unpretentious and hardy Gorky trucks (and based on small buses PAZ and KAVZ 651-651А) was produced until 1975, and the operation survived almost until the 2000s (due to receipt of military storage). Based on them have created many specialized and special machines for many years employed in the national economy and in the army, not only the USSR but throughout the socialist camp.

The third generation of medium-duty trucks GAZ has become the most popular not only in the history of the USSR, but also in the global automotive industry. It was produced over four decades and included economic models: light-duty a 2.5 ton GAZ-52, starting with the 1958-59 models. the GAS-52Ф with an advanced pre-chamber torch engine, until late GAZ-52-04, produced from 1975 to 1989. Total production "52" "gas" was about 1.01 million; medium-duty model GAZ-53/-53A/-53-12 with a lifting capacity of 3.5 to 4.5 t (as upgrade), which received the first petrol V8, released in 1961-1993 years with a circulation of over 4 million, by the way, tens of thousands of GAZ-53 collected in Bulgaria, where they were equipped with a license diesel engine Perkins.

In addition, the series contains a two-ton four-wheel drive truck GAZ-66 cab-over-engine (V8) that was produced from 1964 to 1999 until a late diesel versions of the GAZ-66-41 and GAZ-66-40 mid-late 1990s (respectively, with diesel GAS-544.10 and turbodiesel GAZ-5441). Edition of the famous "shishiga", by the way, the first models of Soviet cars received the "award of excellence", was discontinued in mid-1999 on the figure of 966 thousand by the Way, in 1992-1994 at its base was produced in a limited edition of national economy of 3.5-ton truck (modification of GAS-66-21/-22/-31) with saddle, strapped the rear axle.

The heirs of the Nizhny Novgorod srednetonnazhnye third generation from the late 1980s became the fourth generation of trucks, including both already out of production models, in particular: a 4.5-ton carburetor GAZ-3307 (1989-2013 years), 5-ton GAZ-4301 (1992-1996 with a six-cylinder diesel air-cooled GAS-542) and 3-ton diesel GAZ-3306 (1993-1995 with a four-cylinder air-cooled diesel engine GAZ-544), and is now produced models, including: a 4.5-ton GAZ-3309 (in 1995-1997 with the turbo air cooling GAZ-5441, 2002 – with a turbodiesel MMZ D-245.7 different environmental modifications in 2012-2016 with a custom turbo diesel Cummins ISF 3.8 L (GAZ-33096), and since 2013 – with a turbodiesel YAMZ-5342.10 of Euro-4 (GAZ-33098)).

By the way, the series turbodiesel YAMZ-5342/-5444 today has become virtually the only diesel engine on the line of srednetonnazhnye and diesel engine Cummins ISF 3.8 L after discontinuing the 3.5 to 4-ton truck GAZ-33106 "Valdai" (2004-2015) on other models does not apply, as MMZ D-245.7, which, however, still installed in versions Euro-0 and Euro-2 for export to Egypt and other developing countries with a lax environmental regulations. The fourth generation of complement-wheel drive models, for example, heir to the famous "shishiga" – a series of "Sadko" GAZ-3308/ -33088 and a series of special vehicles "Vepr" GAZ-330811-10 on its base, produced since 1997 and a series of economic trucks "Countryman" GAS-33086/ -33086/ -33086-74 (2005) and "the Huntsman" GAZ-3325 (double cab) with engine, respectively, ZMZ-513 (V8, carb), MMZ D-245.7 (turbo diesel, Euro 0 – Euro 4) and YAMZ-5444 (turbo, Euro-4).

Currently, an increasing share in the production of srednetonnazhnye GAS is already the fifth generation of trucks GAZ – series 5-ton trucks Gazon NEXT (С41R/ С42R), manufactured from September 2014. The series includes the models with short (3.77 m – С41R1) and long (4,52 m – C41R3) wheel bases with a single cabin and C42R1/ C42R3 double cab, with the same bases, and modification of lawns NEXT City with low loading height and reduced turning radius. The main engine of 2015 has become the domestic YMZ-53443 environmental standard Euro-5.

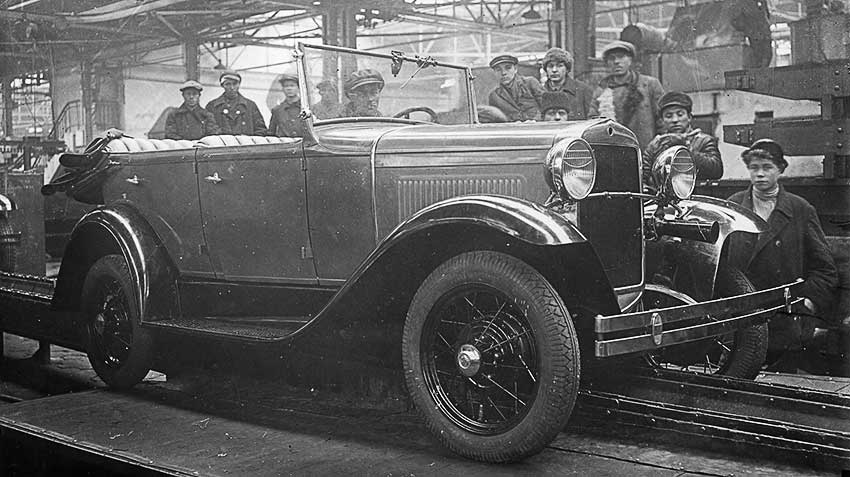

Of course, it is necessary to mention cars GAS, for example, the GAZ-a (Ford-A model 1930 with an open Phaeton body), produced in the years 1932-1936, became the first domestic passenger car mass (41.9 thousand).

His successor GAZ-M1 "Emka" (1936-1942 he 62,9 thousand) – first domestic car with a closed sedan.

Then the postwar "Victory" GAZ-M20 (241,5 thousand) became the world's first passenger car with a monocoque body pontoon shape (for licenses issued in Poland as the FSO Warszawa).

The ensuing "Volga" GAZ-21 (1956-1970), was the first in the country got an automatic transmission (though not for long, as the conditions for its operation were made), was produced in great enough numbers to 639,5 million and became the first Soviet mass exported a car to be successfully sold in dozens of countries.

"Volga" future generations: GAZ-24 (1968-1986 years. 1 million 64 thousand), the GAZ-24-10 (1985-1993 gg., 417.5 thousand), GAZ-31029 (1992-1997, 529,6 thousand), GAZ-3110 (1997-2003), GAS-31105 (2003-2008), as well as the GAZ-3102 (1981-2008, about 156 thousand), while maintaining structural continuity, stood on the line forty years

For most of his life conveyor Volga acted as one of the most popular (although not the most popular) models of domestic production.

The latest passenger model of the GAS was the sedan Volga Siber (2008-2010) made of imported components only in limited quantities (a total of 8.9 million).

Not to mention a range of passenger cars large class: GAZ-12 ZIM (1950-1960, 21.5 thousand) with a monocoque 7-seater body,

GAZ-13 "Chaika" (1959-1981 years, 3.2 thousand)

and the GAZ-14 "Chaika (1977-1989, 1.12 thousand), characterized by elegant design, high comfort and powerful engines, rightfully became the calling card of the Soviet automobile industry.

GAS has become a pioneer in the implementation of\ RVS in our country: from the Phaeton GAZ-61-40 (1940) and sedan GAZ-61-73 (1941-1945) and jeeps GAZ-64 (1941-1943) and the GAZ-67/ -67 (1944-1953 gg.), which during the war produced, and armored car BA-64/ -64B.

Postwar jeep GAZ-69/ -69A (1952-1956), was then transferred to the UAZ.

Since the end of 2012 AZ GAZ went on a contract Assembly of passenger cars on a full cycle (CKD) with welding, painting and Assembly: Skoda Yeti (which from mid-2018 to replace the newest model Kodiaq), Chevrolet Aveo (2013-2017), Skoda Octavia (2013), VW Jetta (2013), and a series of full-metal vans and buses Mercedes-Benz Sprinter Classic (2014). At the moment the contract with GM were terminated, with the Volkswagen Group extended to 2019, with and Mercedes-Benz up to 2021. However, according to statements of the management of GAZ Group retains the rights to the brands "Volga" and "Chaika", which does not preclude their revival in any form in the longer term.

The most revolutionary product to ensure the actual survival of AZ GAS in the "dashing 90" and turning it into the current powerful industrial group "GAZ Group" is the latest lorry GAS-3302 "GAZel" (1994), actually representing a fourth generation of light trucks GAS.

However, its failed predecessors in the face of the model GAZ-56 first generation 1958 (with original cab and chassis) and second generation 1962 (with cab from the GAZ-52) and remained a prototype, as the all-wheel drive model GAZ-62 first generation and the 1.2-ton truck GAZ-62 which was issued only in small series at the turn of the 50s and 60s. Promptly appeared in the midst of market reforms lorry turned out to be a blockbuster and private carriers, and representatives of small and medium-sized businesses, as well as various government agencies – from the municipal to the power. The huge popularity of the series "GAZelle" added the emergence in late 1995 tsmf GAZ-2705 immediately offered in cargo and passenger 7-seater version of the "Kombi". In the spring of 1996, the series has gone 8-seater minibus GAZ-3221, supplemented in the autumn of the same year, 13-local version of the GAZ-32213 "minibus taxi", as well as sanitary version of GAZ-32214.

Without exaggeration, this model LCV caused a revolution in the mass transportation of passengers across the entire country, making it taxi is hardly a monopoly of passenger transport in a number of cities across the country and abroad. However, monopoly in any segment – a two-edged thing, since the mid-2000s, it is the "GAZelle" was to undergo a certain stigma both from the media and passengers, as overtly permissive policy of the authorities in relation to staffing of drivers cited for the wheel mass of the minibus, a huge percentage absolutely unfit for people, which led to a certain growth of accident rate. However, with the design of "GAZelle" has been improved (there were stabilizers of stability in the suspension and ABS), in addition, were banned and withdrawn from service so-called "converted" from conventional vans of the machine, not fit for passenger transportation.

At the end of 1998, the series went lighter "1-ton" family "Sobol" (GAZ-2752/ -2217 and -22171), which successfully supported an older series. In 1999 appeared the first in the history of the Gas van "Barguzin Sobol" GAZ-2217. After restyling 2003 series "Sable" and added an onboard GAS-2310, previously produced only under the order. Sorry, never went into production well successful prototype delivery van-van GAZ CityVan units of "Volga", presented at several exhibitions in 2006. The model is similar to the name of the GAS showed only "commercial vehicles 2015" in the form of van on the basis of "Barguzin". However, this did not stop Gas just to certify the van "Sable" as a lightweight commercial model with full weight up to 2.5 tonnes, which opens her travel outside the capital "cargo frame".

A qualitatively new level of security and comfort ensured the emergence of the next generation of trucks Nizhny Novgorod – series GAZelle NEXT. In 2013 started the production side of the model A21, year – demand version A22 double cab and bus body frame-and-panel type, in 2016 launched the release of the tsmf, which at the end of last year was presented to a van, designed primarily for corporate and long-distance transport.

Today Gas customers have the broadest choice of buses and LCV and MCV. By the way new models of buses belonging to the Group of GAS producers (PAZ, LIAZ and KAVZ), now carrying the signature emblem of the GAS.

The share of GAZ Group on the LCV market is 6 months of 2017, 74% (76% for the same period of 2016) in the segment side, 35% (31%) of tsmf and 44% (36%) in the segment of minibuses.

In the segment of srednetonnazhnye (LDT), the share of Gas increased to 71% (70%). In the segment of front-engined buses, the percentage increased to absolute 100% (99%), 64% (45%) in the segment of urban and 56% (52%) in the segment of intercity buses. In the segment of heavy trucks (HCV), with the brand "Ural", the percentage increased to 39% (36%). On the powertrain market share of GAZ Group was 32% (34%) for heavy diesel engines, 38% (22%) on average diesels and 37% (36%) fuel systems.

Exports increased from 2012 from 23 to 46 thousand in 2016, and the plan for 2017 is 51 thousand For the development of export established company, GAZ International, and developed plans to penetrate 15 priority markets in Asia, Africa and Latin America. In the priority plans for development of export of R & d include: vehicle engines of Euro-6, the introduction of ESP, downhill brake airbag right steering, as well as the development versions for a hot and high-mountainous climate.

For 2017 GAZ Group has mastered in February – low cost version of the 12-metre low-floor bus LIAZ City; in March – gas-diesel version of the Ural NEXT; in April – frameless isothermal van Gazon NEXT has a low entry and a 9.5-metre midibus Cursor, in August – 13-seater minibus "GAZelle NEXT", the GROOVE-3204 "Accessible environment" with low entrance, updated liner "Cruise" (for 2018) and also a comfortable crane-based Ural NEXT; in October, a school version of frame and panel bus "GAZelle NEXT" and "Ural NEXT" with double-cab; in November, the series went to the gas equipment for YAMZ-530 CNG fuel equipment YAZDA Euro-5 Common Rail under YAMZ-536; December scheduled the debut of the "Gazelle NEXT 4,6 t" (C41R92-80 with diesel engine Cummins ISF2.8S-5161P class Euro 5) which my colleagues, by the way, I managed to see in the shop as a test of a manual for collectors,

in addition, before the end of the year there will be a small bus Vector NEXT 7.1 (7.5 m) and unified with him on the chassis of "Gazon NEXT 10t" full weight 10 tons (they have changed the front and rear suspension, and power of a diesel engine JAMZ-534 increased to 170 HP) and a large city bus. By the way, the plans for 2018 to 2020 – development of a reinforced frame and rear axle for "Lawn NEXT" and NEXT Vector, and a 210-horsepower iteration of a diesel engine JAMZ-534/ -534 CNG, 6-speed manual gearbox, 600 N·m and automatic transmission at 800 nm appears the model of "Lawn NEXT 12t" total weight of 12 tonnes and the longest is already a mid-size bus Vector NEXT 8.8. In addition, it will be possible the launch of a series tractor series С47 for working in a roadtrain full weight up to 16 tons.

Modern continuous line of GAS includes traditional series LCV "Sobol BUSINESS" and "GAZelle BUSINESS", including in four-wheel drive options "4x4", and a series of "GAZelle NEXT" (C21/ C22). Class of srednetonnazhnye (MCV) is presented as a modernized GAZ-33098, GAZ-33088 "Sadko" and GAZ-33086-74 "Countryman" and a new "Lawn NEXT" in odnoimennoy (C41) and two-cabin (С42) versions. Buses represented prefabricated models A63 and A64 is presented to the school version. A series of "Sobol BUSINESS" received in 2015-2017 upgraded gasoline engine EvoTech 2.7, a new instrument panel, rolled side of the loading platform side, and four-wheel drive version with a double cab GAS-231073 "Sable-farmer". For the year 2018 outlined the emergence of the electronic control transfer case (for 4x4 versions) and the fuel tank larger capacity. For "GAZelle" is planned IT-way – from simple maintainability in the 2000s, for the best reliability in 2013, and "intelligence" in 2018. this includes: ADAS+ESP (front camera, front and two rear side radar control unit, the system MirrorLink (automatic image transfer from a smartphone to the Central display of the car) and CAN-bus. The last three positions included in the block of telematics, which also include: GSM module, fuel level sensor, pressure sensor TPMS (tyre) and panic button.

In terms of powertrains the GAS has signed an agreement with Volkswagen for the use of turbo diesel VW for promising export versions of "GAZelle NEXT" with GVW of 2.8, 3.5 and a 4.6 so At the last the largest (15.5 m3) version of tsmf and a 20-seater version of the bus on its base (in perspective wireframe models with low input type Vahtan) provides installation betterbudgeting VW motor and 6-speed manual gearbox GAS (460 N·m) or automatic Punch company. Of course for the domestic market will continue the use of gasoline engines Evotech and Cummins diesel engines ISF2.8L, 5-speed manual gearbox on the 250 and 330 N·m. the creation of the chassis for 4.6 tons total mass also demanded the emergence of ESP, a new rear axle, disc brakes in a circle, but in turn allowed us to lengthen the wheelbase and widen the on-Board platform.

In the development of electric Gas you intend to move in mid-2018 from the existing prototype tsmf "GAZelle NEXT" Elektro sample 2016, to small-scale production of electric vehicles, and further, due to joint development with MSU on the motor and organization of packaging batteries as well as the development of other components, to create the electric car of new generation. In 2019 scheduled uniform electric chassis for the entire range of LCV "GAZelle NEXT", which when capacity is 1250 kg achieved reserve in the urban cycle 120 km (recharge time – 3 hours), maximum speed 110 km/h (acceleration up to 60 km in just over 10), to overcome the rise in 25%. The most promising segments for electric vehicles recognized in addition to passenger traffic, auto shops, food trucks, mobile health centres and service centres, etcE. such application where mileage is minimal, but the ability to work in a green and pedestrian areas is a priority.

Directly to visit the production, I will discuss in the next section.

.

|

|

|