BOSH took a course on localization in Russia

24.05.2019

The Bosch group intends to deploy a cutting edge manufacturing

The Bosch group was held on may 23 in Moscow the annual press conference, which was briefed on its achievements in 2018 and plans for the near future.

The turnover of the Bosch Group, a leading global provider of technology and services in Russia in the 2018 financial year amounted to 1.2 billion euros (91 billion roubles). "In the continuing difficult economic situation in 2018 Bosch managed to retain its positions on the Russian market. "The chosen strategy of development of local production gives excellent results", – said the President of Bosch Group in Russia, Ukraine, Belarus, Central Asia, Mongolia and the Caucasus Hansjurgen of Overstolz. In 2019 we plan to continue the strategy of strengthening localization in Russia. For Bosch, Russia remains a market with high potential of development, production localization and collaboration with regional partners form the core of the global strategy of the company. This year we plan to continue to expand our partner network and to cooperate with Russian research and educational institutions in the field of digital technologies and the Internet of things."

In Russia, Bosch operates 3,700, and the amount of the Group's investment in the development and modernization of production capacity in 2018 reached 21 million euros. In addition, this year Bosch for the first time entered the Top-10 of the hundred best employers of Russia according to the leading Russian online recruitment platform HeadHunter.

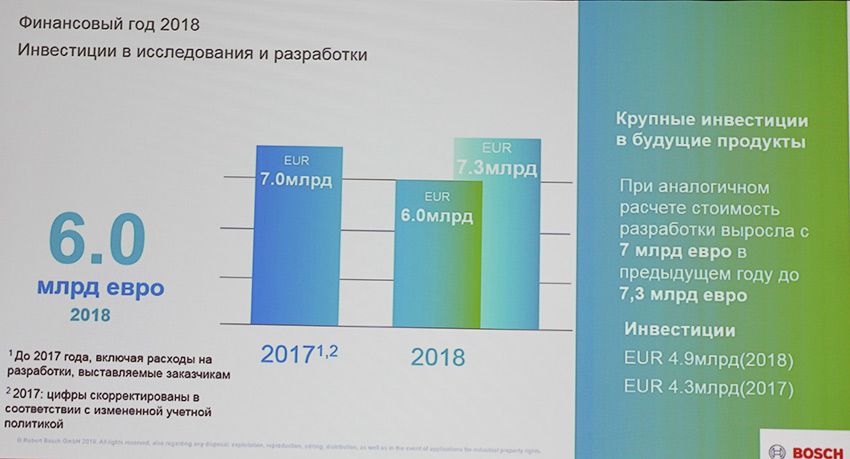

Research and development

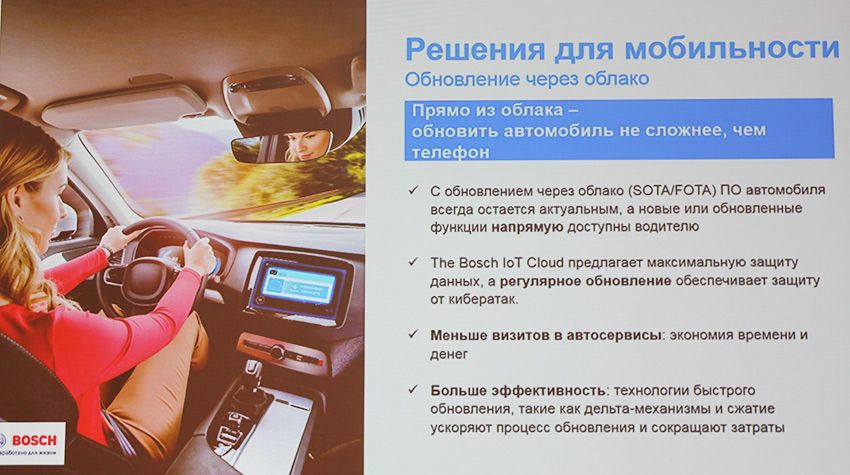

Bosch is cooperating with the innovation center SKOLKOVO in the field of technology, based on artificial intelligence (AI). This is one of the key expertise of the company. In the next ten years all Bosch products will either be an AI or be developed or created with it. In 2018 Bosch signed an agreement on cooperation in the field of artificial intelligence, applied mathematics and information security with several Russian universities and scientific and educational institutions, including the SKOLKOVO Institute of science and technology (Skoltech), St. Petersburg state University and Spbpu (Polytech). Among the objectives of the joint development - analysis of braking systems and road damage based on sensor data, the application of computer vision and deep learning for detecting defects in material and manufacturing automation, cybersecurity, generation of aesthetically attractive products based on AI and smart agriculture.

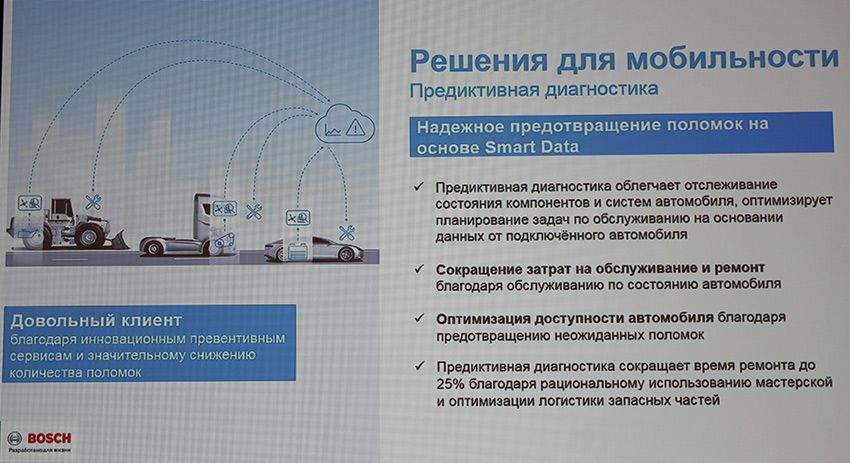

Centre of outsourcing and monitoring at Bosch Global Service Solutions has implemented a modern integrated approaches to automation in customer service and redesign the business processes of customers. In 2018, the center's specialists have conducted more than 1.5 million consultations, and thanks to the emergency call service has saved over 5 thousand lives. Based on AI methods and remote diagnostics innovative monitoring technologies are applied in different fields of activity — from preventing breakage of the aggregates to the control of complex systems.

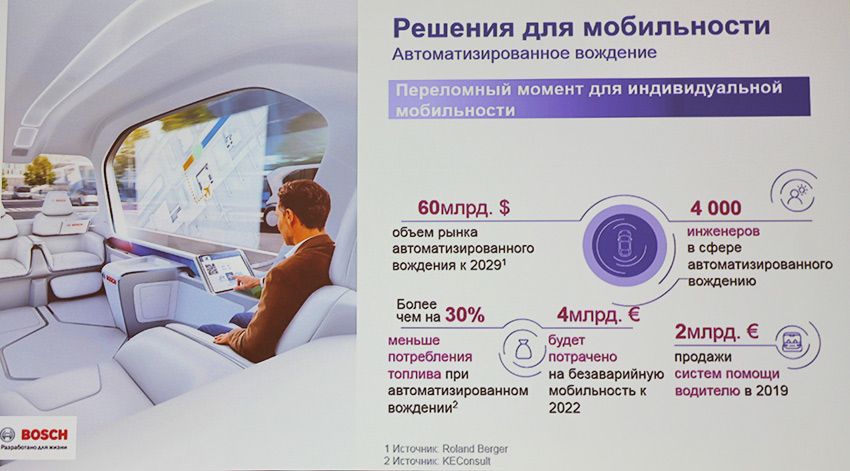

mobility Solutions

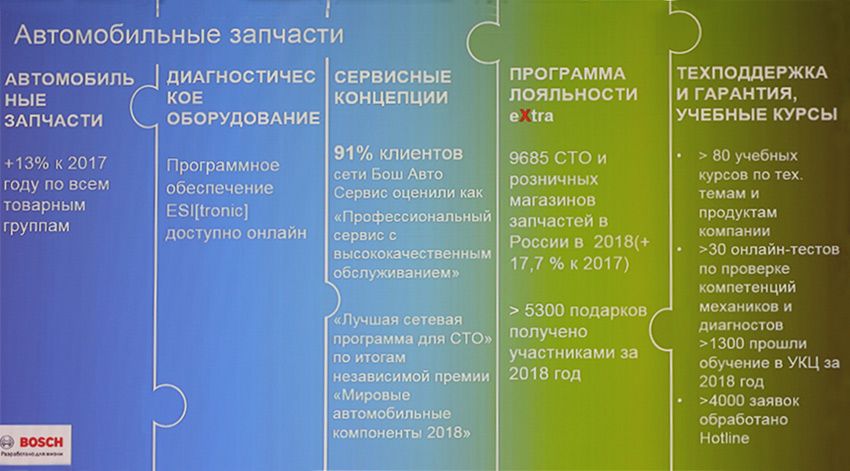

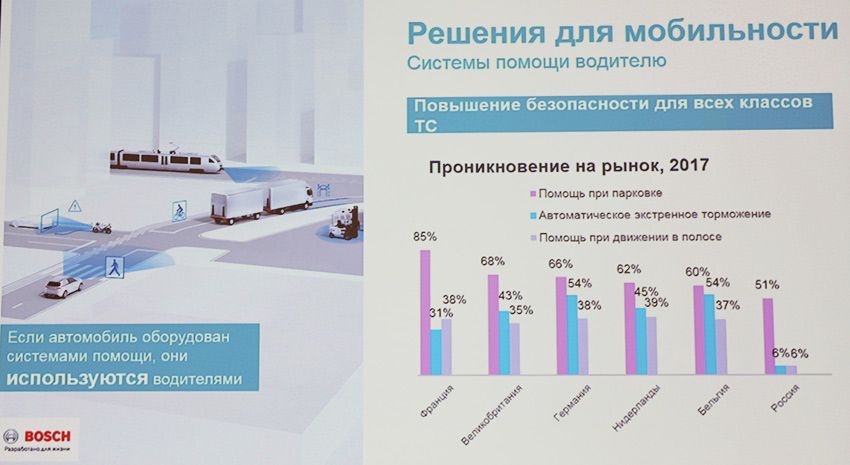

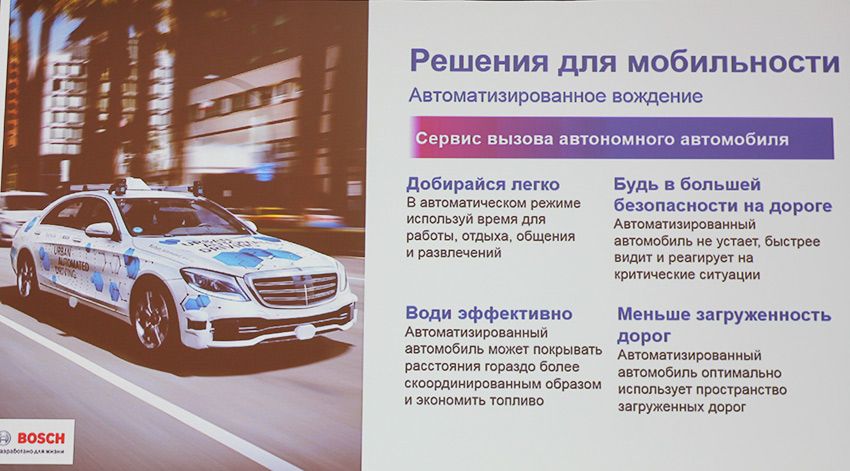

For the direction of mobility Solutions 2018 fiscal year was also successful: the business unit of automotive components was developed and grown with the market. Every year Russia has increased the number of new vehicles that have active safety systems Bosch, which in turn has a positive effect on road safety. This confirms the status of Bosch as the world's leading developer and manufacturer of ABS systems.

Network of Bosch Car Service in 2018 was also awarded the prize "Global Automotive Components" in the nomination "the Best network concept for service". The network remains the largest in Russia, while continuing to develop its loyalty programme eXtra workshops and shops of auto parts: the number of its users increased by 18% compared with the 2017 year.

Diagnostic testers Bosch KTS and released in 2019 ESI[tronic] online help services to service control units are common vehicles using the most complete technical information. Another first was the EBR database (Experience-based Repair), containing descriptions of the frequently used faults.

In addition, in 2018 in Training and consulting center Bosch has trained more than 1 300 people, and a hot line technical support and service processed about 4 thousand applications.

automation of industrial objects

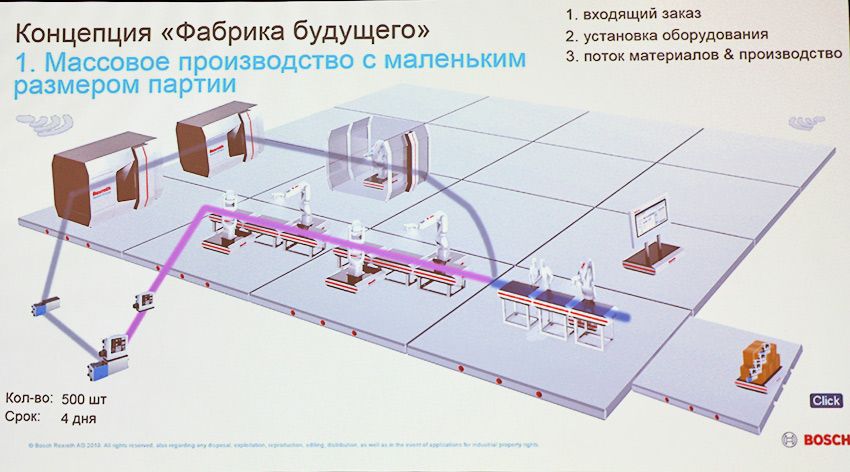

The Industrial technology continued introduction of innovative products and integrated solutions for the automation of production processes in Russian enterprises.

"Bosch Rexroth" in conjunction with the system integrator "WREN solutions" conducted a comprehensive modernization of the automatic line multi-step processing of the clutch at the company Valeo in Togliatti. The project used a system of numerical control Bosch Rexroth MTX, drive systems IndraDrive M servo servo MS2N.

Bosch is actively involved in the Russian-German GRID initiative, which brings together commercial and public sectors in the field of digital economy and industry 4.0.

Combat climate change

This year, Bosch expects slower economic development. Despite the challenging conditions in important to Bosch industries and regions, the company expects the level of sales in 2019 will exceed those of the 2018 Regardless of the short-term Outlook, the Bosch Group intensificare efforts to combat climate change and improve air quality.

"Climate change is not science fiction, it is happening in reality. If we take seriously the Paris agreement, the fight against climate change we need to consider not just as a long-term task. It needs to be solved in the short term, said Dr. Volkmar Denner, Chairman of Robert Bosch GmbH, at the annual press conference. - We also focus on the satisfaction of the public related to air quality in the cities. We are leaders in innovation and strive to provide technological solutions to environmental problems."

That's why Bosch is stepping up its already successful efforts to reduce emissions of CO2.

"We will be the first large industrial enterprise, which will reach such ambitious targets like zero carbon emissions a little more than a year. From 2020 onwards, Bosch will bring to zero the carbon footprint, said Denner. - Carbon dioxide emissions all 400 locations worldwide will be zero in 2020".

On the other hand, Bosch is also committed to achieve ambitious targets on air quality: "We want to reduce air pollution from transport to almost zero. In finding solutions we are not limited to the hood of the car," said Denner. The company's work to reduce the concentration of pollutants in the air to almost zero level is based on three main principles: Bosch develops technologies for power units with low levels of contamination, works with municipalities on projects to maintain stable traffic flow and introduces its own system of mobility management in their units. For example, the plant in Samara is already using efficient temperature control to avoid loss of warm and cold air in the shops and other premises: the building has a good insulation, the unused spaces are not heated, used Central air-conditioning system. With the same purpose, the building is equipped with sun blinds. With the aim of saving electricity, the plant uses the LED lamp.

In the near future it is planned to install wind turbines research has shown that in this area the force of the wind meets the standards of efficient use of the system. Also discussed is the installation of a solar collector..

|

|

|