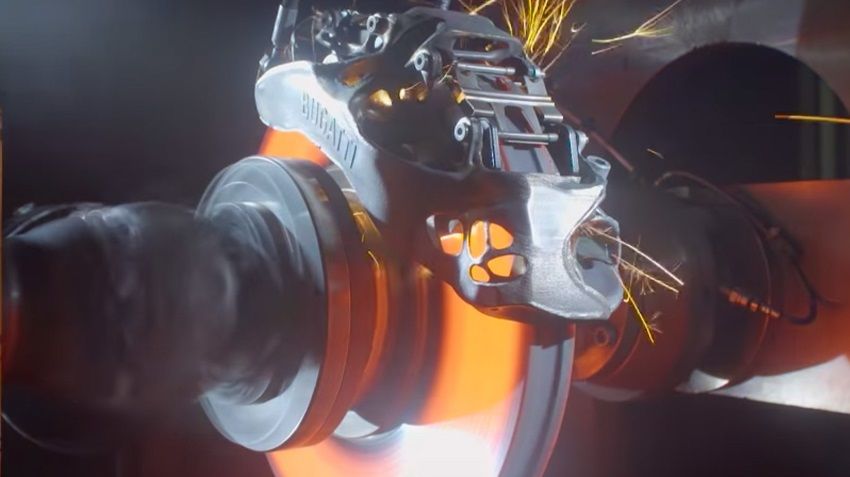

Video: what will become of 3D-printed Bugatti brake caliper in hard test

25 December 2018

Bugatti started to print out the brakes on the printer

For the production of super-expensive cars are the advanced technology. Recently used 3D printing. In particular, the Bugatti this method produces the brake caliper. Now the company unveiled a test video of this part in truly extreme conditions.

Caliper printed on a special 3D printer using titanium powder. The detail is formed in layers. In total, the production of one part takes 45 hours!

But the result is worth it. As you can see in the video, the temperature of the brake mechanism at the factory tests, more than a thousand degrees Celsius. Brake disc becomes red-hot, the pads start to strike sparks. But not one item was damaged. This test simulates emergency braking from a speed of 400 km/h.

Thanks to the technology of 3D printing, the engineers managed to lower the weight of the brake caliper by 40 %, from 4.9 to 2.9 kg. And we are talking about unsprung mass, which depends primarily on the comfort and controllability of the vehicle.

|

|

|

Element was not found.