Volvo construction equipment refuses 2020 from a diesel engine in the segment of road-building machines

22 May 2019

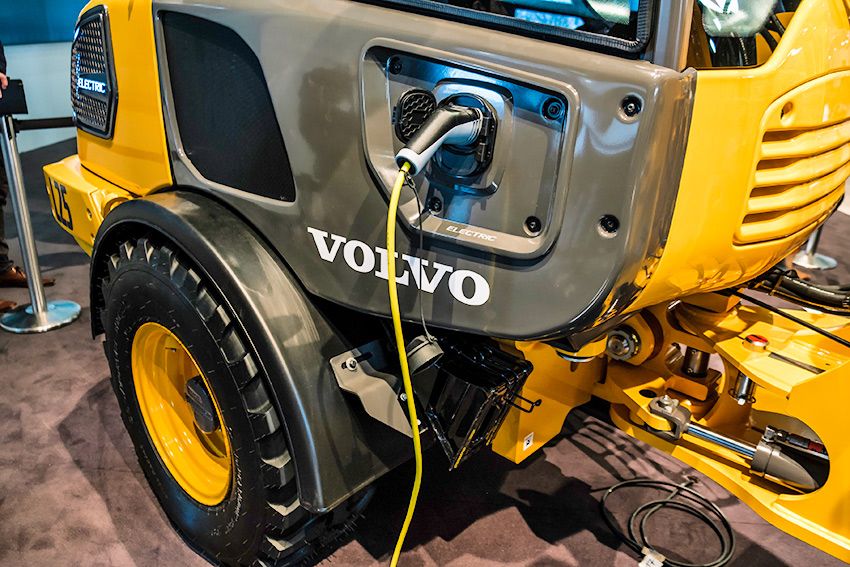

Volvo CE was presented at BAUMA 2019 first front loader L25 Electric and Electric miniexcavator ECR25

From more urbanized cities to rural farms compact construction equipment is gaining more widespread. Presenting at BAUMA 2019 in Munich its first electric compact excavator and wheel loader with zero emissions Volvo Construction Equipment (Volvo CE) performs their program "building the future".

The machine, which fell first to demonstrate a new electric line of compact excavators and compact wheel loaders Volvo CE, of course, provide zero emissions of exhaust gases and a much lower noise level, reduced costs by switching from conventional diesel to electricity, improving the efficiency and reducing the amount of maintenance compared to their conventional counterparts.

Since the mid-2020 Volvo CE launches a whole line of electric compact excavators (from model to EC15 EC27) and wheel loaders (from L20 to L28), in General, through stopping the development of new models of diesel engines.

The transformation models ECR25 and L25 in electric was due to the replacement of internal combustion engines for lithium-ion batteries.

So, ECR25 Electric equipped with lithium-ion batteries and a single electric motor that drives the hydraulics to move the machine and drive of the hinged equipment. The battery Electric ECR25 allows you to work for 8 hours, for example, in the repair of local utilities. 1 hour the battery can be charged to 80% capacity, and from a household network with a voltage of 230V – 6 hours fully. The total weight of electroinactive – 2.5 t, the breakout force of the bucket – 20,2 kN maximum digging depth – 2.76 m and a maximum blade height – 3.07 m.

Front-loading electric forklift L25 Electric produces virtually the same performance (8 hours, 80% charge in 2 hours and 12 hours for a full recharge from a 230-volt charger). Its total weight 4.9 t, tipping load is a 3.35 t, the strength of the gap is 49 kN when the load forks of 2 tons, bucket capacity is 0.9 m3. Blade height equal to 2.5 m. Machine suitable for use in municipal work, the landscaping, gardening and agriculture. L25 design also includes two specialized motor, one for transmission and one for the drive hydraulics. The separation of the subsystems possible to increase the efficiency of individual systems and the whole machine.

Both electric machines ECR25 and L25 is equipped with built-in chargers that allow charging over night via a normal household socket. The option of quick charging requires more powerful chargers will be available later.

Director of electric and automation of Volvo's Scott young says: "ECR25 and L25 is a revolutionary machine that demonstrate a commitment to the future of Volvo CE technology. Because they are electric – in the environment do not fall solid particles, nitrogen oxide or carbon dioxide. This, together with the fact that they have very low noise levels, makes them ideal for use in cities and densely populated areas."

In parallel, the Swedes have promised to continue to work on finding new opportunities for the introduction of electric drives on all of its road-building models and in all applications..

|

|

|

Element was not found.