To hit the electric vehicle according to the environment

24 December 2018

To become more environmentally friendly diesel engine, electric vehicles need to be in operation for 9 years

Norwegian University of technology NTNU, has published a study according to which electric vehicles to become more eco-friendly than a conventional car with internal combustion engine (ICE) and, consequently, to justify the emission of harmful substances in the manufacture of traction batteries, to operate it should be about four when compared with a gasoline car, and when compared with diesel – all nine (!) years. Here's a grandmother and deselect! Of course, that in Europe and four years are already a time limit for the operation of the machine, and only for 9 years the lion's share owners definitely will substitute their cars on batteries for a new one. Is that prosperity (despite anti-nuclear lobby), France, in which the electricity industry is traditionally based on nuclear power plants (over 90% of electricity produced) more optimistic about EV – hence the emphasis on them from PSA and Renault.

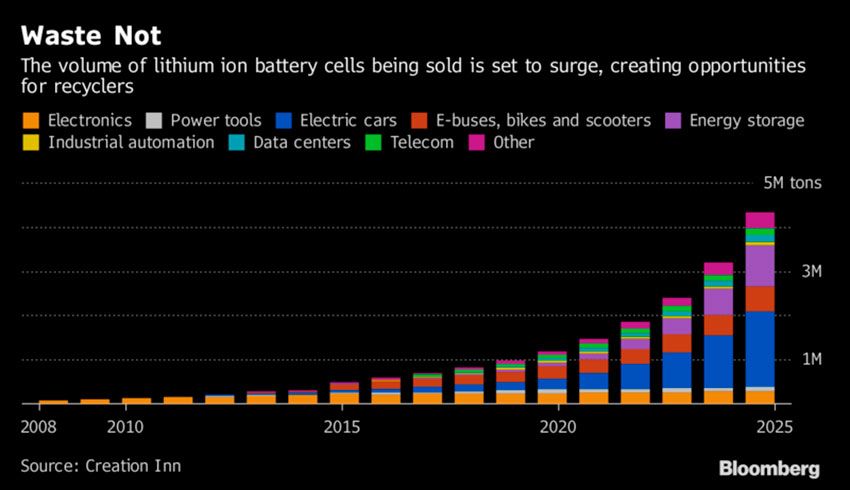

According to Bloomberg, by 2025, electric cars and buses (the blue and red part of columns) will produce the largest share of lithium-ion battery recycling

Germany and Denmark, joined by UK and Ireland focus on wind and solar energy, but the same China and India, but also by leaps and bounds developing the so-called "alternative energy," still sitting tight on the needle of traditional energy, i.e. coal and it will be decades before they will be able to get off it. The farmers in India and China have already started to complain about the deterioration of the environment due to battery waste. And what will happen to the ecology of these countries when the world market of electric vehicles and, therefore, batteries will grow by 2030 at least 50 are estimated to $100 billion?!

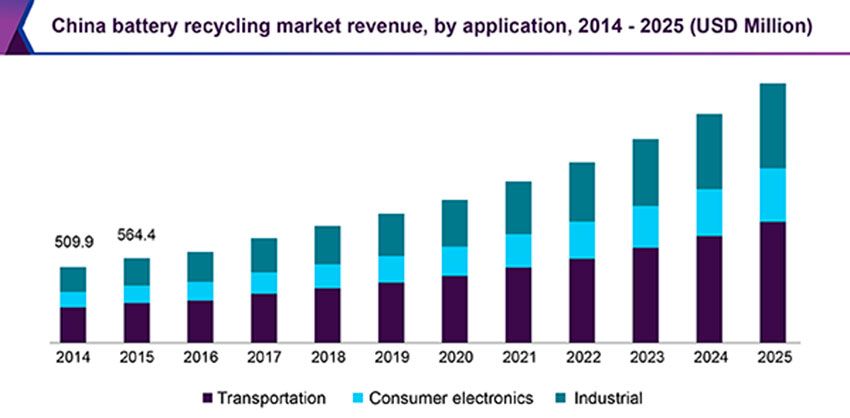

This chart clearly shows how is growing and will grow the Chinese market the recycling of rechargeable batteries in China from 2014 to 2025 (also the lead is vehicle)

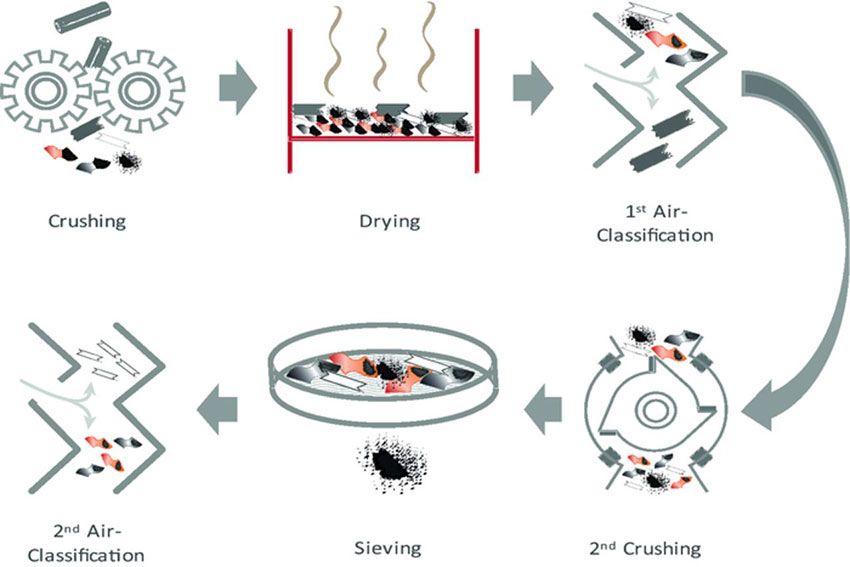

The main problem will be the question of the disposal of batteries based on lithium (toxicity immediately following radioactive waste), cost-effective technology for recycling which are developed with great difficulty, mainly due to the great cost and secrecy (trade secret) specific composition of the batteries, which use cobalt, Nickel and graphite.

The principle of recycling Li-ion batteries have long been known (see also a diagram on the splash screen), but to make it cost-effective so far no one succeeded

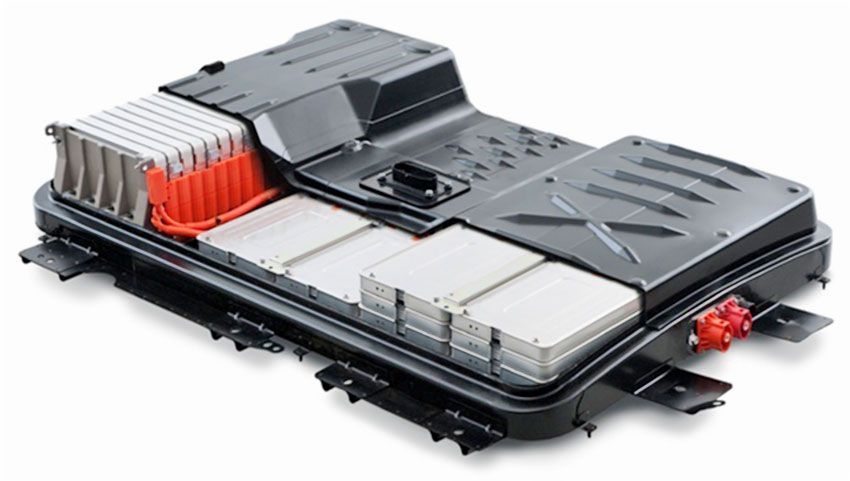

This problem is quite reasonable even attended the Formula 1 world champion Sebastian Vettel. Yet another solution for the disposal of very impressive battery containers, weighing a hundredweight there except palliative (actively pushed by Elon Musk, by the way) for using stranded (up to 70% of original capacity battery) for an average 8-year life in the larger funded stations, by the way, is strictly necessary for efficient and commercially viable exploitation of wind (often idle day and less effective in seasons of low wind) and solar (don't work at night and are less effective in winter at high latitudes) plants.

Here's an illustration of the idea promoted by Elon Musk – used in electric vehicles batteries then serve at the storage power plants

As a result, the electric vehicle is the final factor of air pollution (which he pollutes as if "indirectly") for today is significantly inferior to conventional cars with internal combustion engines (ICE). Suffice it to say that the share of energy (and hence emissions) required to manufacture conventional car is only 15% of the total amount of emissions over its life cycle, while the electric car – they make up more than 50%, including because of the huge energy costs occur during the extraction of raw materials and development of materials necessary for the production of batteries. While that promises to reduce dependence on rare-earth and just polluting materials in the manufacture of batteries, remain only promises to eliminate their shortcomings on new types of batteries. In the meantime, such projects (with an absolutely fantastic levels of consumption and environmental friendliness as in "sea water") more PR different startups from the energy sector, but the serial EV none of these battery systems "new generation" has not yet found application.

"Processability" of the current lithium-ion batteries today is at a measly level 5% (left on the photo – developing lithium)

The cost of extraction of lithium batteries is five times greater than investments in its production ($7700 per ton)! The second important element of the battery (from 15 to 5% by weight) – is not much less toxic cobalt (value $25,000 per ton of lithium-cobalt), today it is extremely difficult to recycle. But, by 2025 (which is tomorrow) at landfills would be about 11 million tons of batteries from electric and hybrid cars! And technologies for the recycling yet, including because of the already mentioned trade secrets of composition.

Lead-acid batteries are recycled 99%

By the way, against this background, the archaic, but for today, super-massive lead-acid starter storage batteries look just the same, the environmental samples, since only in the US, for example, the level of recycling reaches 99.8 percent, and worldwide it is quite high – lead (value $1400 per ton of oxide) are today mined all over the world just from old batteries, but not from the mines.And yet even today not dispose of battery byword, namely mining them for materials (rare earth metals mainly). For example, the main flow of lithium give Bolivia and China. So, here in Bolivia because of development of deposits of mining companies have already destroyed a large part of the Delta of the Rio Grande, the habitats of many fish (just fish) of the Amazon basin. The extraction of cobalt (without which the battery life reduces dramatically) in the main (66% of the world market of this metal) is conducted in a "Democratic Republic" of the Congo, and, in fact, the hands of young slaves (pretty social and class basis for raspiarennyh technologies of the 21st century!). Also, a significant part of the current batteries have Nickel and graphite. Production of Nickel is also very toxic, causing, for example, had to cover its production in Australia (mining companies just did not pull the creation of treatment facilities), and we have these problems quite good Norilsk residents. Well, graphite is cheaper to obtain and synthetics from oil (by the way, hydrogen for fuel cells, too, is produced from methane). Hence, the need for these materials will continue grow exponentially, including all the negative consequences for the planet. But as they say, even not yesterday to address the issue of recycling lithium companies, for example, California Toxco: "currently, there is no profitable business model for recycling lithium".

Batteries from Nissan LEAF – produce in times easier than to dispose

So, what is "environmentally friendly" electric car, for which he so ardently loved the "green" in particular, and the wider liberal Western community? No real reduction of emissions over the life cycle of the vehicle (including its production), and in implementation of the liberal green political-economic "model of society", in fact, oborachivaetsya a new round of cleaning the pockets of ordinary citizens of the "Golden billion", smoothly flowing in a new round of neo-colonialism, in its present stage mixed rare earth metals. Moreover, the environmental left installation (read essentially hypocritical) in a given country, the wider it focus on alternative energy in General and electric vehicles in particular.

Formula-E – just PR or the real future?

Even in the already hyped professional Formula E, as AR rightly says, there is no answer a single practical question of the development of EV technologies (e.g., improving the design of batteries are simply prohibited by the rules, and all participants go on the same type of battery) and confined only to the external form of racing electric cars and "licking" directly to the actuator. OEMs (e.g. Nissan) do not ignore the disposal problem, but much progress has not see..

|

|

|

Element was not found.