Tesla digs "ditches" for competitors

9 August 2018

For a number of advanced technologies batteries and electric vehicles Tesla can become a monopolist

Legions of analysts from the automotive industry and Finance for a year predict of Tesla Inc. imminent collapse, but even record losses doubled in the second quarter of 2018 did not collapse, but rather to the growth rate of its shares on 11%.

Paradox? Only if we approach the issue from a traditional point of view. Forbes magazine suggested that to consider the production Tesla on the other hand, for innovations that are not soon will be able to master its competitors.

The concept of Moats ("barriers") to create fundamental advantages in their product (technological and(or) market) before competitors, has created a multi-billionaire (!) Warren Buffett, whose fortune in the spring of this year amounted to "only" $100,1 billion, in addition, it occupies 16-e a place in consequence in the world according to Forbes magazine. Interestingly, the owner of Tesla Elon Musk is its fiercest critic, but is actually zealously and very successfully brings to life.

Remember that the old traditional autoproduction (for example, the former head of the concern FCA), who oversaw the startup of Tesla, was to claim that de in "electric car" the Mask there is nothing of the sort, which they would not be able to quickly copy and reproduce in greater numbers and at lower cost. Accordingly, they say when they come to mind "take the field", then all the problems of electric cars will be solved in the light, but the "upstart" Tesla or will disappear entirely or will move to the periphery of the new growing market. However, everything flows, everything changes. Of course, the huge transnational autoproduction, indeed, have a powerful R&D centres and the experience of many decades of mass production of traditional cars, however, and the "California upstart" was not so simple.

About the horror lithium cobalt deficiency

One of the fundamental arguments about the "futility" of the development of electric vehicles is often limited stocks of lithium because of its rare status. So that the sharp increase in the production of electric cars without running the risk of shortages and price hikes, but this ignores the fact that rising prices for raw materials is always a great occasion for the commissioning of fields with a lower concentration of raw materials, which at high (and especially ultra-high) prices still becomes profitable to produce. And lithium, is usually produced normally on the shores of salty lakes, not an exception.

In addition, it is prudent Tesla was able to contract the largest shipments of lithium from the Americas.

In addition, according to estimates by Forbes for the release of one of electromobile battery 100 kWh requires not more than 10 kg of pure lithium, respectively, to produce 1 million electric vehicles per year will require not more than 10 000 t of lithium and to produce 100 million electric cars, i.e. full replacement of their world production of conventional cars with internal combustion engines – only 1 million tons of lithium per year. As for today the world produces about 60 000 tons of lithium per year, the price increase will dramatically increase the size of commercially viable reserves.

More acute today, by the way, is the problem of cobalt used in the electrode of batteries to improve their capacity and number of recharges, i.e. service life. Over the past year, prices for the metal soared quite substantially (to $75 000 per ton and more). But, more importantly, two-thirds of the production of cobalt in the Democratic Republic of the Congo, where illegal mines (naturally without treatment facilities) even use child slaves!

Today, almost all competitors Tesla among traditional car brands use the NMC-batteries (Nickel-manganese-cobalt), where the proportion of cobalt is 15% by weight SB or about 360 g/kWh of battery capacity. So for the battery the British fashion electrocreaser Jaugar I-PACE requires about 33 kg of cobalt, and for a compact American electric Chevrolet Bolt at 21.6 kg. Moreover, this number significantly exceeds the amount of lithium required for the production of these electric vehicles.

In the short term, Tesla is going to reduce its dependence on "socially dirty" of cobalt to zero

Accordingly, Tesla uses different technology with a Nickel-cobalt-aluminum batteries (NCA) which require no more than 220 g of cobalt on the kWh capacity of the battery. Even the "long-range" version of the Tesla Model 3 Long Range requires less 17.2 kg of cobalt, and the base budget version that look forward to next year, will cost less than 12 kg of cobalt. Mileage per charge is comparable to the Chevrolet Bolt, but on demand, in the cobalt – almost twice it is more economical.Besides, Elon Musk has already broadcast said that next year Tesla, in General, can abandon cobalt cathode. None of the competitors, true, but the Chinese BYD such a breakthrough promises. Yes, BYD uses the technology of lithium-iron-phosphate batteries, the density of stored energy which is much smaller than the Tesla battery.

When size matters

Today Tesla has achieved much greater energy density of their battery than any of its competitors. So, its bestselling Model 3 is equipped with a battery, composed of 4416 elements cylindrical format 2170 (21х70 mm). The average energy density of such a battery submodule block – 223 WH/kg, and cylindrical element of 270 W•h, Respectively, to competitors, for example, I Jaguar-Pace and the Chevrolet Bolt need a battery of higher mass, which in turn increases the operational energy consumption of electric vehicles and directly reduces the range of its run.

One reason for this progress battery (manufacturer Panasonic) electric cars Tesla became its de facto monopoly on the use of cylindrical elements, while all other work with larger prismatic elements, the main advantage of which is considered to be more simple Assembly process of the battery. In addition, such battery formally higher energy per unit volume. For example, a single battery Chevrolet Bolt comprises a total of 288 elements, unlike several posted a battery at the Tesla around the bottom. For large automakers, in General, typically involving third-party component manufacturers, as well as the desire to save space inside the car body.

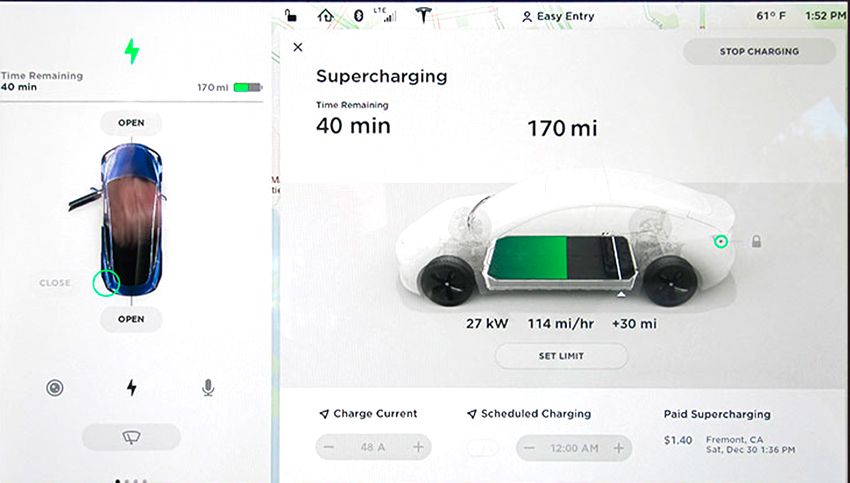

Fans of the brand Tesla appreciated that the charging characteristics of electric vehicles are always consistent with the stated in contrast to the inflated values of its competitors

However, this approach as every coin has its flip side. So, a lot of small elements in the Tesla battery is inevitably mounted with an increased clearance relative to each other. Accordingly, the distance from their centers to the cooling of the tape (surrounding the cylindrical element) is only a centimeter. And this, in turn, allows them to avoid overheating, unlike the larger prismatic cells. Between such cylinders it is easier to have effective liquid cooling, moreover, they are potentially less prone to General ignition of all the elements in an accident. But even more importantly from a consumer point of view that these batteries can actually charge and recharge faster than batteries of the competition with less risk of overheating.Yes, the battery is in the back of the electric car more space, but paradoxically, this makes the interior of the Tesla models larger in width and length than the competition. "Smeared" at the bottom of the battery is located in a horizontal plane and does not affect the capacity of the compartment (the distance between seats and(or) the capacity of the Luggage boot) with the same wheelbase. Besides a half-ton battery serves as a natural stabilizer while riding, lowering the center of gravity of the machine, causing the electric car becomes more resistant to skidding and flipping.

Although the competitor the Nissan Leaf, the battery is also located under the floor, but she performed on prismatic elements, and with air cooling, which causes great problems in real life.

Individual element of the battery from a Nissan Leaf in 15 times, and the Chevrolet Bolt – is 10 times larger than Tesla Model 3. Hence significantly increases the charging time. So, electric cars GM and Nissan for 30 minutes of charging can get the energy to run only 140-144 km And so say the advertising data, but in reality things are much worse due to overheating structurally insufficiently cooled battery.

For example, the developers of the Jaguar I-PACE argue that the future of their electric car can drive 200 km after 30 minutes of charging. However, this will only come when "public filling stations will receive the necessary technical improvements". Until then the buyer of the machine cost from $68,000 to ensure only 135 kilometers after 30 minutes of charging. At the same time, Tesla Model 3, exactly for the same half hour allows you to charge the battery to run at 270 km.

Besides, unlike other automakers, Tesla now has quite an extensive (and growing) network of fast-charging stations (of superchargers), available to owners of its electric cars already are today. Competitors also have to build on the progress in the expansion of the "public charges", which today is still drastically less than superchargers Tesla.

a Barrier of energy efficiency

The energy consumption per kilometre for electric cars is much more important than for conventional cars with internal combustion engines, which in the worst case often have to drive to the gas station, where they spend very little time on the filling process. For electric cars the same, lowest possible energy consumption per kilometer of distance traveled is a critical operational target also directly determines the power reserve and the battery capacity.

New Tesla Model 3 beats the competitors (Chevy Bolt and Nissan LEAF) is not only the advanced design of the battery but also the perfection of body structure

And here Tesla also provided on the occasion: thus, the new Model 3 is highlighted, first, the lowest among all production cars in the world drag coefficient Cx=0.23, while the Bolt it is, for example, of 0.31. Such a flow body provides a very moderate battery consumption on the track. Second, here on the rear axle are applied, the main motor at a constant current, the efficiency of which is 5-10% higher than that of motors with alternating current as almost all the competitors. Such motors competitors chose because of their greater prevalence and technical "familiarity".

The drive rear axle Model 3 used a more economical electric motor DC, as "smeared" on the floor of the battery lowers the center of gravity of the entire electric car

As a result, the battery Model 3 with a capacity of 78 kWh allows you to travel on a single charge 537 km on the EPA cycle. From a competitor I Jaguar-PACE the capacity of the battery is 90 kWh, but the mileage on one charge does not exceed 480 km, respectively, from the Chevrolet Bolt at the amount of energy in a 60 kWh – mileage is only 383 km. the Numbers run, measured in different cycles far more important than what you can get in real life. In fact, today the mileage per charge for electric vehicles is fundamentally important only on a country road, as the city for the typical driver mileage in 537 km per day quite excessive, however, American car owners used to move considerable distances (300-500 km) in normal cars, I think this reserve is critical when choosing an electric vehicle.On the track thanks to the excellent aerodynamics Model 3 at a cruising speed of 120 km/h can pass 443 km (480 km at 113 km/h). The reserve Chevrolet Bolt at the same speed only 305 km away.

Quick charging as a new consumer fetish

Again, we should mention the benefits of better cooling the battery. If Model 3 the promised speed cannot charge and in reality, neither the Nissan Leaf nor Chevrolet Bolt this number does not pass. The fact that the manufacturers of these BEV measured the charging speed of the car with a fully discharged battery, also cooled after the Parking state. In reality, the user almost never charges his electric car on the road that way. He previously riding on it, why the battery with prismatic elements, of course, overheat. Hence, controlling ACB electronics does not give the same Nissan Leaf charge faster – in half an hour you can "upload" only 50 km instead of the promised 140 km!

On the large display Model 3 the driver can clearly see the charging time and the value of a possible run

Although, with this the Chevrolet Bolt in two and a half times better, as it provides liquid and not air cooling large prismatic cells, but they cool well and quickly fails. So 30 minutes really charged Bolt only 112 km.When Tesla goes bankrupt

In fact today it turns out that in the most promising segment of electric vehicles with a large reserve of practically useful models of electric cars except for Tesla, no one produces. As a result, major competitors in the face of the LEAF, Bolt, and most likely I-PACE the current versions will remain on the American market niche products because of adaptation to long journeys.

Today that Tesla became the de facto monopolist in the production of electric vehicles for the full travel (in the photo electrocreaser Model X trailer-caravan)

So, it turns out that Musk is a very successful technological dug "trenches" (the battery, aerodynamics and the network of superchargers), through which competitors won't be able to jump, as existing battery technology and platform for electric invested a lot of money. But we are actually talking about the fact that the traditional automakers actually have to give up their current patterns of electric vehicles and batteries in the scrap and immediately switch to a Tesla-like technology. B even in this case there is a danger that by the time they catch up to the current technological level Tesla is not excluded that it will be able to "dig up" new "ditches" (e.g., in the form of a compact Model electrocreaser Y), entrenched as a monopoly, with a practical electric vehicle applications.

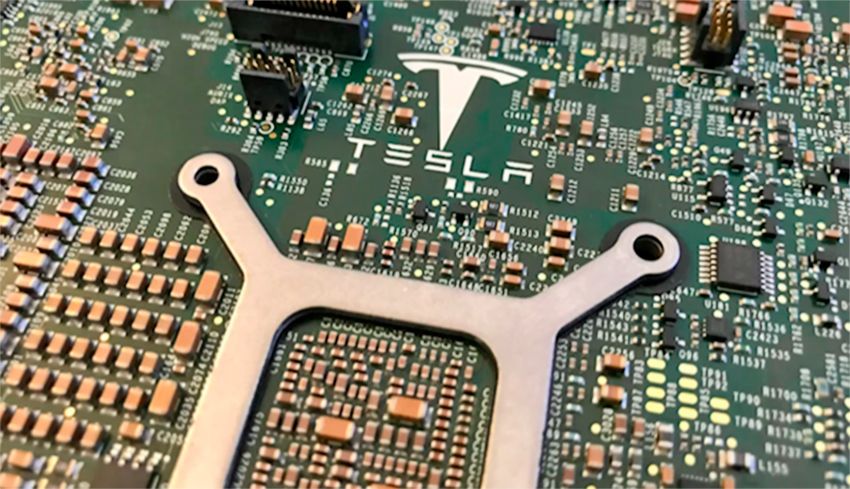

Despite the problems Tesla doesn't stop at the development of drones and started making their own chip Hardware 3.0 for them

In addition, during the announcement of the unprofitable results of the second quarter Elon Musk announced that the company is developing own chip Hardware 3.0 for controlling unmanned vehicles that are able to make a dent in the monopoly of nVidia, producing the same chips. Another possible barrier in the way of prosecution of its competitors..

|

|

|

Element was not found.