Nissan refuses to manufacture its own batteries for electric cars

7 August 2018

Nissan Motor announced the sale of battery division of the AESC due to the fall in demand in Ontario

Nissan Motor company, which was the first among the world's leading automakers launched the modern large-scale electric car Nissan LEAF, and announced the sale of its subsidiary units for the production of batteries Automotive Energy Supply Corporation (AESC) of the Chinese company Envision Group dealing with renewable energy sources. On the completion of the long prepares the business of the transaction the company announced on Friday 3 August.

Nissan was one of the last OEMs batteries for their own electric cars

The last straw for the company Nissan Motor was the decline of sales of electric vehicles in the most populous canadian province of Ontario, after here was canceled benefits for their purchase. Although other regions of Canada may be able to compensate for the failure of sales in the local market, while about it to speak still early. In July, the market of electric and hybrid cars in Canada fell by 47% to 3362 units.Nissan has independently developed the traction batteries for its electric cars, starting in the 1990s, and today remains one of the last OEMs with a complete production cycle EV supplying electric drive system other automakers, for example, the French Renault, which is located in the corporate Union. Nissan now joins the majority automakers that purchase batteries for their electric vehicle from specialist electrical manufacturers.

A plant for production of lithium-ion batteries Sunderland in the English will also go to the possession of the Chinese company Envision Group

CEO at Envision Group Mr. lei Zhang said, "with this strategic acquisition, we implement its desire to expand its activities by investing in the new company, which will help the implementation of innovative technologies according to the concept of the Internet of things, intelligent transportation (Vehicle-to-Grid) and lower emissions in cities".

The first generation of electric car LEAF equip too quickly degraded by the Nissan battery capacity of 24 kWh

At one time batteries (with a capacity of 24 kWh) produced by AESC, which were used in early versions of the Nissan LEAF have met problems with the durability, so in some cases they have lost capacity after only one year. Nissan was the only major automaker that used a battery with cooling air.Other automakers have turned to such suppliers, like Panasonic Japanese and Korean conglomerate LG Chem to supply battery for its electric cars, and using liquid cooling. For example, Tesla has established a joint venture with Panasonic for the development and production of battery cells for its electric cars. In turn, the same LG Chem supplies batteries to such automakers as General Motors, Volvo, Hyundai, Kia and others.

Independent experts examined the Nissan battery capacity drop, which took place on 30-kilowatt batteries three times faster than at the same 24-kilowatt

Although Nissan has improved its capacity, but studies have shown that its battery is increased to 30 kWh of capacity, with 2016 set for the restyled model of the first generation LEAF, was degraded more rapidly than the previous 24-kilowatt.

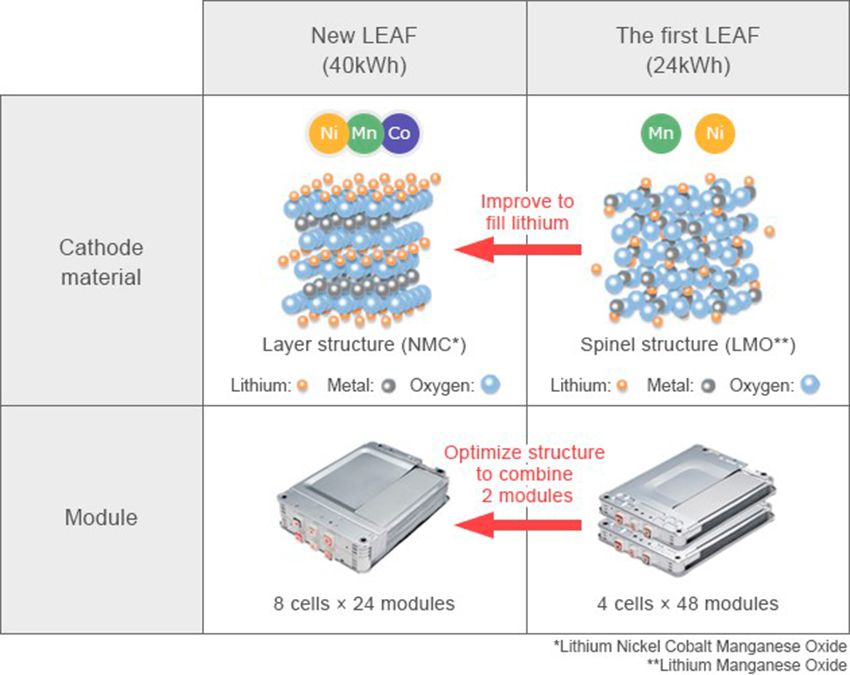

40-kW battery Nissan sample 2018 design has been seriously reworked, but from further own development of the battery of the Nissan refused

For the latest generation battery with a capacity of 40 kWh Nissan has developed a new Nickel-manganese-cobalt cell with a new multilayer structure, designed in particular to reduce the loss of unit capacity. This design provides greater capacity and power (8 items 24 cells) than the previous Nickel-manganese with a disordered structure (4 modules with 48 cells) while the total number of cells equal to 192-m, saved. This battery is 37% higher capacity and 67% more powerful compared to an early 24-kilowatt model 2010 or 33%, than 30-kilowatt sample of 2017. While it is only 0.9 mm thicker than the predecessors and according to Nissan due to a more optimal design of the battery has a reduced number of points possible overheating.

The concept of Nissan LEAF e-Plus 2019 demonstrates that in addition to increasing the battery's capacity by 1.5 times, the novelty will receive and futuristic design

In 2019 model year Nissan plans to introduce new (upgrademy) version of the LEAF EV e-Plus with the increased power reserve which will be used for battery capacity has been increased to 60 kWh supplied by the company LG Chem.

The Nissan LEAF 2019 model year instead of its own battery appears 60-kilowatt Korean, however, the reserve will increase only up to 240 km, vs the expected 400 km

Assembly line of the AESC plant in Sunderland

Among the sold production capacity AESC consists of a parent factory batteries at Nissan's Smyrna, Tennessee, as well as facilities in England and Japan. It is expected that the production lines for the production of batteries will be kept in operation so as to Envision herself working on a new generation of batteries and technologies for connected electric vehicles and integration of networks Vehicle-to-Grid..

|

|

|

Element was not found.