The motor wheel Protean360 + will allow electric vehicles of the future to Park in any side

23 July 2019

"Corner module" Protean360 + make Parking trouble-free unmanned shuttles

A British company, Protean Electric has proposed the concept of the latest "angular module" – universal motor-wheels with 360° rotation, combining in one product the innovative technology of electric transmission, steering and suspension, which can revoljucionerov urban vehicle of the future, including unmanned shuttles.

The module, named Protean360 + is considered the first of its kind, designed for commercial use, offering the possibility of rotation on 360° in the vertical plane. In addition, the module includes innovative ultra-compact pneumatic suspension with height control ride height and high efficient and powerful integrated motor ProteanDrive.

Module Protean360 +, intended for urban vehicles of the next generation allows you to move people and goods smoothly and efficiently in the busiest streets of the city. The compact design of the module allows you to create a vehicle with a fully flat floor cabin, providing a comfortable stepless entry and exit, on the sides and front (!) the door of the Shuttle, which is especially convenient for wheelchairs and strollers, ensuring mobility for all. Accordingly, the vehicle can Park in front, back or sideways to the curb, and passengers can disembark directly on to the pavement without stepping on the carriageway.

Exceptional maneuverability, provide 360-degree steering system allows convenient and fast to move through the busy city streets and to Park in the most confined spaces, this is pristykovyvayas to the curb. After stopping the Shuttle's pneumatic height Adjuster suspension Protean360 + allows the machine almost to "kneel" by lowering the floor of the car exactly to the level of the sidewalk, which allows for smooth and almost smooth space to transship the goods or roll the wheels of wheelchairs and baby strollers, as well as to enter and leave the children and elderly people with limited mobility.

CEO of Protean Electric K. Y. Chan explains: "the Program of urban mobility "Transport as a service" is gaining momentum, and with it arises the need for a new class of city vehicles for public or private use, a passenger or for delivery of goods, manned or Autonomous – all of these new vehicles require new technologies that will allow implementation of all these tasks. Accordingly, the "corner module" Protean360 +, created on the basis of innovative technology, allows to fully meet the requirements for such urban vehicles of the next generation".

Chan said: "an Angular module Protean360 + intelligently combines advanced, but it is already production-ready technology. Its unmatched capabilities significantly increase the effectiveness of the concept of city vehicles and we are already negotiating with potential clients wishing to use the angle module in its future vehicles."

TECHNICAL INFORMATION

Steering with a circular rotation

The ability to rotate each wheel through 360° without restriction, delivers exceptional maneuverability of the vehicle.

Autonomous vehicles will still have to respond to the complex configuration of a stationary street objects, and to respond to unexpected obstacles in their way. Absolute maneuverability, provide multi-turn steering all four wheels (similar to the one held by a hand trolley in the supermarket – ed.) means that the car will not need to stay to complete even the most complex maneuvers. Module Protean 360+ will help to minimize the risk that the vehicle will encounter a situation in which it will not be able to smoothly and safely turn around. The trip will be less prone to failure or delays for passengers and, not least, for all other road users, helping to streamline traffic flow and minimize traffic jams.

Since angular modules allow the vehicle and to rotate 360° within its own external dimensions, it allows him to continuously move through the narrow city streets and narrow turns, for example, at junctions and in Parking lots and loading yards. And, most importantly, it will provide the maximum accuracy piparkoogimaania directly to the curb.

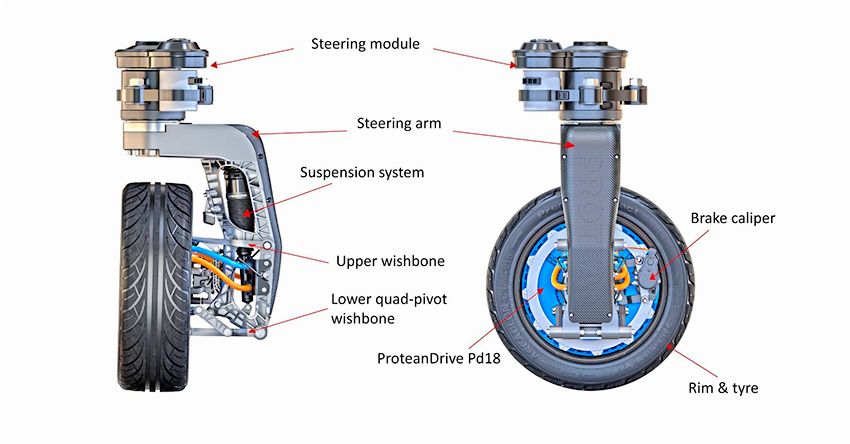

The possibility of rotation on 360° is made possible thanks to the patented rotating device, which is located above the main lever angular module. The upper part of the rotating device attached to the vehicle, and its lower part is attached to the module bracket.

Unit electric power steering (acting at the wire) is located above the module, so that the axis of rotation is directed to the lower part of the wheel.

To rotate the lower part of the module docked interface cable engine control, hydraulics and pneumatic system height control suspension module, which is connected to the second static interface inside the hub motor wheel. During the rotation module 360° arm also rotates 360° and all drive components rotate together with it. As a result, when such connection cables are not twisted and not ground.

New two-wheeled suspension for compactness

The main problem for the suspension system of the module was the creation of a compact circuitry required to provide a minimum volume of the unit inside the vehicle, allowing you to create a flat floor for passengers or more space for cargo. To create a compact scheme the team proposed a new multi-link suspension system with separate lower hinge of the control arm.

The patented kinematics "spider" with double wishbone and four pivot levers ensure both the compactness of the layout, and to ensure the full suspension stroke. This arrangement provides optimum suspension geometry and an additional joint in the lower control arm to achieve the desired kinematics, while maintaining extremely important to the compactness of the suspension. It also allows this suspension to show the same behavior in all directions.

As a result, the construction of a single module optimized for all four corners of the vehicle, eliminating the need to create left and right or front and back versions of the module, thereby reducing the cost of its development and production.

Pneumatic ride height control enables the vehicle to "kneel"

Pneumatic control system the ride height allows you to raise or lower the height of the body. The bellows and the compressor used in conjunction with other vehicle systems and provide independent control of the suspension height of each module for precise control of the level of the floor of the car.

Super-efficient, fully integrated motor

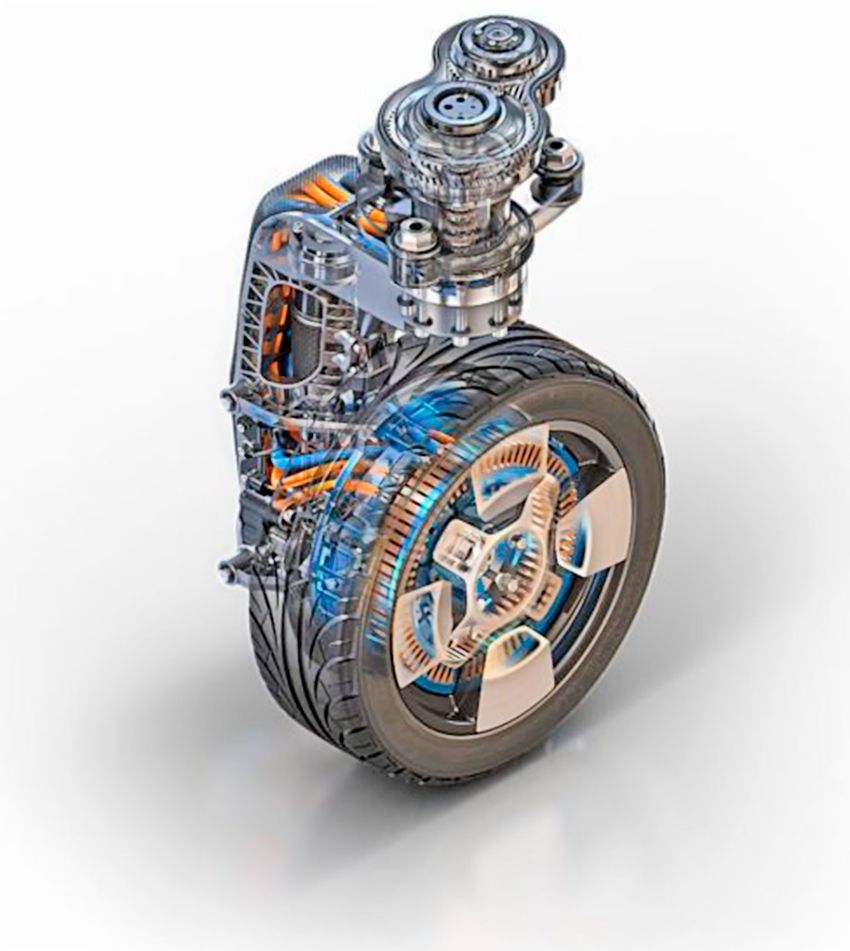

The actuator includes a patented integrated motor ProteanDrive, which combines motor and inverter in a single drive device. It is much more efficient than alternative types of drive, due to the elimination of losses in transmission.

Motor-in-wheel motors also provide more dynamic control of the total power and torque. They can change the vector of the torque within milliseconds, which means improved performance of ABS, ESC and traction control system that improves safety, directional stability and shortens the braking distance (by approximately 7%, according to an independent study). In addition, this system provides a high level of redundancy, especially when the diagram with four modules, because if you experience problems with any single engine's power can be transferred to other modules.

ProteanDrive is a synchronous motor with permanent magnets and integrated inverter and a special water circulation system, that are all tightly Packed in the wheel rim. Brake friction disc and brake caliper is also built into the wheel ProteanDrive, complementing its system of recuperation when braking.

The motor rotor is directly connected to the hub, transmitting torque from the engine to the wheel, eliminating mechanical loss at power transmission. Configuration direct drive reflected in the design of the engine ProteanDrive high torque and low rotational speed (this is a fundamental problem of the motor-wheels are still not allowed to implement them on cars at least dimension dump trucks – ed.). The engine is equipped with external rotor to maximize torque with this configuration, which allows you to install rare earth magnets on its surface without the retaining elements, which otherwise could reduce the power of the motor-wheel. Accordingly, the engine ProteanDrive Pd18 (for mounting 18-inch wheel) develops a maximum torque of 1250 N•m and peak power of 80 kW (107 HP).

PS it looks Like the company ProteanDrive managed to circumvent the main problem of the motor-wheel – inconsistency of the rotation speed of the rotor of the electric motor and the wheels of the car, which had to be built into the design of the planetary gearbox, highly ataglance design, and it's unsprung weight, which is extremely negative impact on the ride and even limits the achievable maximum speed. In addition, it reduces the efficiency of the entire design of the motor-wheel, therefore, so far most EVS traction electric motors lead wheel via CV joints themselves are located in the body, soE. in the area of the sprung mass. The same rotation of the steered wheels through 360° allows the machine to fabricate such somersaults that police turn seem childish prattle..

|

|

|

Element was not found.