Volvo Trucks introduced the unmanned tractor without cabin

18 September 2018

Conceptual Volvo Vera predicts that robotaki will do without the cab

In recent years, Volvo Trucks has sozdaniem fond of drones, and, in escabinos architecture. Suffice it to recall the mining truck HX01 Prototype, which was named best product of the year by the Swedish Institute for quality (SIQ).

Now it is the turn of unmanned trunk electrotractor. It was called Vera.

As Vera will affect the transport industry? How safe is it? Is this technology reliable? Vice President, technology, Autonomous Volvo solutions with Volvo Trucks Mikael Karlsson responded recently to these and other frequently asked questions.

How did you make this decision, as Vera?

Bold innovation and a willingness to take decisive steps – an integral part of the DNA of Volvo Trucks. Traditionally we have taken a phased approach to product development, but as somebody once said to me: "you can't build a ladder to the moon". It may seem that you are getting close to it, but you'll never get there. You need something radically change. When we started this project, we asked ourselves the question: what will be the perfect transport solution in the future? Then we used the "approach to the rubber band", where he expanded our horizons and see what we can do today to achieve our vision. The concept of Vera, in fact, our way of creating something that will become our guide into the future.

Faith is just a concept or is it something we are likely to see in the real world?

Concept Vera has become a complement to our current package. This project is still in the development stage because we need to take the necessary steps to ensure that all aspects of safety and provide our customers top-notch solution.

What Vera offers customers?

For Volvo Trucks it is important to offer a premium experience by providing our customers with safe and reliable transportation solutions. We believe that Vera can be a faithful companion on this journey.

How will this affect the transport industry?

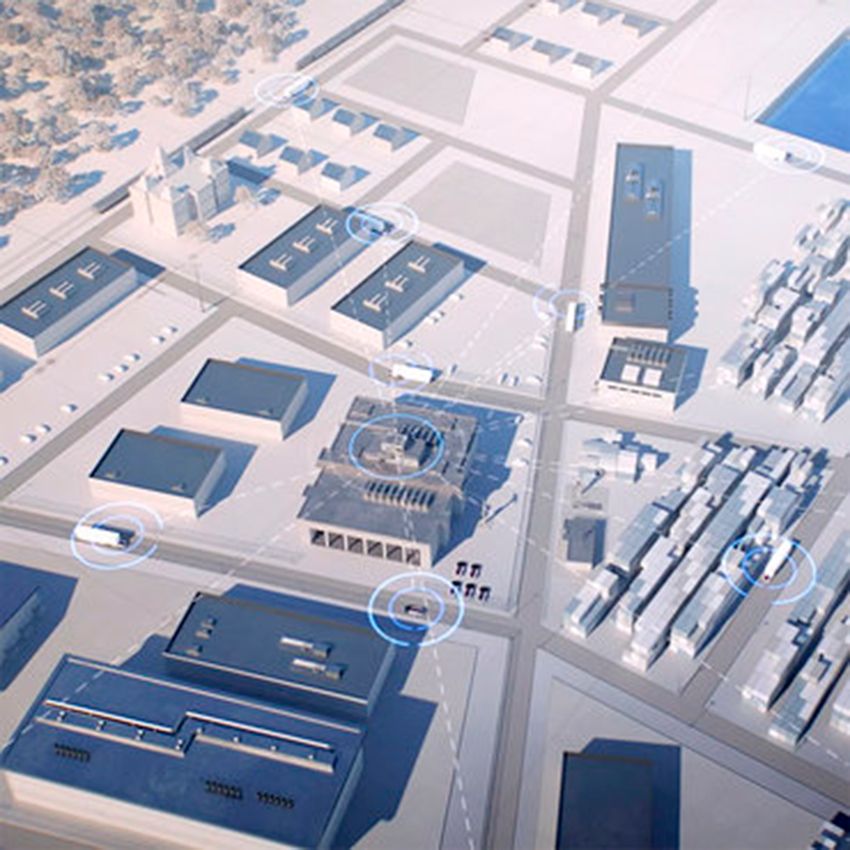

In places such as ports and mega logistics centers, I think we will see a much higher on-time delivery and superior flexibility and performance. Today's logistics operations are often carried out in accordance with the standard daily schedule of transport and port workers, but the decision as Vera opens the possibility of continuous full-time work and serious optimal flow. This, in turn, can minimize the necessity for storage of components and increase the overall productivity in the workplace.

How will this affect society?

Round the clock logistics can mean accelerated time delivery of consumer products. Moreover, since the electric tractor is made, the company may potentially benefit from the elimination of exhaust emissions and road congestion, and reduce noise.

This technology has already been tested?

When creating Vera we integrate new technologies both in the vehicle and surrounding infrastructure, so as to ensure their joint operation requires extensive testing. However, since many basic technologies taken from existing products Volvo Trucks, they pretty much have already been tested. For example, the electric powertrain is the same as on our freight cars, which have recently been introduced to the market.

How this technology will affect truck drivers?

It is obvious that it will impact on the demand for drivers, but in the overall picture of the future given the rapid growth of international and online trading, we foresee increased demand for qualified drivers. I firmly believe that advanced technologies promote the prosperity and advancement of society forward. Today, many factories in some parts of the production is already highly automated, but some still lack the participation of the people. I believe that the transport industry will develop equally with the other production sectors. I foresee that the increased level of automation where it makes sense, for example, to solve repetitive tasks. This, in turn, will contribute to increased demand in former truck drivers in other areas.

Safe Vera?

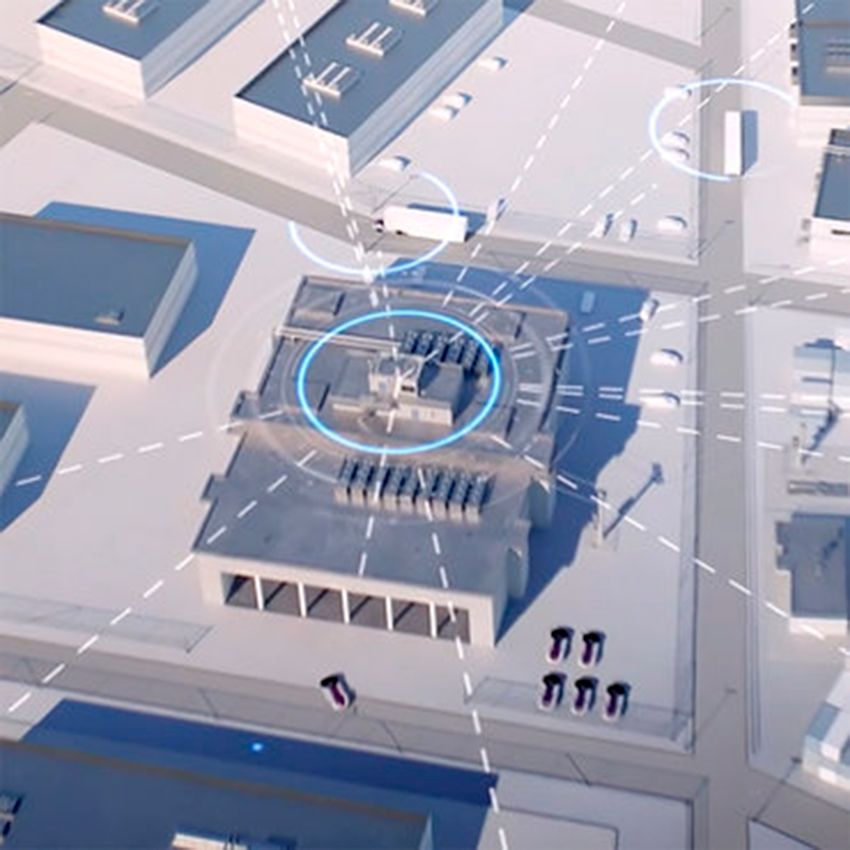

Everything we do is designed to ensure the safety for which we take all necessary precautions. We look at what is necessary from the point of view of infrastructure, vehicles and the control center. Unmanned vehicles equipped with several sensors, radars and cameras are still practiced at lower speeds. Starting with a lower operating speed and drive in a confined space, we then gradually increase the speed and the road infrastructure that gives confidence in the safe automation of commercial vehicles.

What is the next step for Vera?

First, we will work on short distances and with the same load. As soon as we get more experience we will be able to apply it in other areas. However, Vera is not intended for universal application. This is a decision we're going to adjust from user to user, depending on their individual needs, so partnerships with clients will become an important part of the project.

The operator in the future control center, can at any time through remote access via the Internet to control how the location of the vehicle and its technical parameters, and deliver the goods. Yet shown is actually a scale model of an unmanned electric rail tractor, but actually riding on the public roads unmanned road train – in the future, the timing of occurrence of which Volvo Trucks does not report anything yet, and while will develop the technology together with clients.

PS it Seems that the solution with the "amputation" of the cabin while maintaining the traditional layout of the chassis and hence the standard length of the train is not the best option for the future of unmanned trains, as too many unproductive length of the front part of the tractor. Definitely here there is still room for optimization of both the tractor and the aerodynamics of trains in General. Maybe that will increase the length of the semitrailer and a piece of equipment ensure that automated driving will be located directly on the front wall of the trailer. The increase in logistics performance could lead, for example, to the abandonment of the technology of articulated road trains as such, if the train will be loaded-unloaded faster than it is now including automating forklifts, because the behavior of single car safer, for example, in the winter and mountain roads..

|

|

|

Element was not found.