Protean Electric lift motor-wheel to the OEM-level

30 December 2018

Company Protean Electric creates alliances to advance the motor wheels to the global market

American company Protean Electric announced the beginning of cooperation with the firm smart mobility Human Horizons within the company Wuxi Weifu e-Drive Technology (a joint venture formed by Weifu Group, and for the production Protean motor wheels model Protean Drive Pd18) for the development and production of motor-wheels.

The partners plan to build a manufacturing plant in China, to supply a motor-wheel on a global scale.

The world's first workable electric car, the Lohner-Porsche Mixte Voiturette 1900 on motor wheels

The idea of a motor-wheel electrically powered for the first time made the inventor Wellington Adams more in 1884, by placing the traction motor inside the wheel, but connected it through a difficult ball, then the idea worked a number of inventors, including 23-year-old German engineer Ferdinand Porsche, later of the legendary Creator of "Volkswagen Bug" (VW-11) and self-propelled guns "Ferdinand" (Elefant Jagtpanther), which adopted, since in 1897, participation in the development of practical motor-wheel, which was first applied in an electric vehicle, and

Hybrid gasoline-electric Mixte Hybrid (driving its Creator Ferdinand Porsche) with 4 in-wheel motors made a splash at the world exhibition in Paris, but then failed the rally

in 1900 at the world exhibition in Paris, the designer showed the world's first hybrid gasoline-elektricheski the car on 4 motor-wheels, i.e. he was still all-wheel drive.

by the Way, having failed as a powerplant for a passenger car, the powertrain and then became popular on large commercial vehicles, such as fire departments and double-Decker buses. However, then the idea stalled, as too high speed motors required the use of too heavy and bulky gear that increases the weight of the motor-wheel, and as it relates to the unsprung masses, the comfort and controllability of such hybrid (electric car) was uncompetitive. And to overcome these inherent problems, at least on the scale of regular passenger cars never worked out literally to the present day. At the same time on super-heavy (90 tons capacity) mining trucks electric transmission with in-wheel motors have found application since the 1940s, and successfully applied to the present day.

The lifting in the world 450-ton BelAZ-75710 dump truck just would not have been possible without motor-wheels for all the bridges

Still, the idea of implementing the motor wheels for easy automotive remains committed, because it is the most compact, simple (in theory) and the energy-efficient transmission scheme, but still perfectly combined with all modern electronic active safety systems, starting with ABS, there were followers, including in the face of French tire group Michelin and American company Protean Electric.

The last firm gradually towards the creation of practical design. Its system, called Protean Drive was successfully tested on some of the models of cars such as the Ford F150 pickup truck, coupe Mercedes-Benz SLS AMG Coupe, hatchback, Volvo C30 and the Vaxhaull Vivaro van. For example, in December 2012 the authoritative American magazine Car & Driver even brought the motor-in-wheel Protean Drive the ten most promising technologies of 2013. In the course of its development was obtained 23 patents. On the production sample, the company entered in April 2013, and full production planned to expand in 2014 at the newly-built factory in China. However, the reality was more complicated and now the company Protean Electric vengeance is looking for partners, the most promising of which, of course, are Chinese.

Circuit device a motor-wheel Protean Drive Pd18

Motor-in-wheel Protean Drive system is designed for use on hybrids (including, of course PHEV) and electric vehicles (BEV). Its indisputable advantage is the easy adaptation to already manufactured models, as well as the possibility of using for the conversion of cars with internal combustion engines in hybrid (by fitting instead of the non-powered wheels). With such in-wheel motors is possible to implement the front-drive, rear-wheel drive or all-wheel drive diagrams powertrain and regenerative braking. Set Protean Drive itself includes a compact electric motor, inverter and control unit with the software, and all of the above fits easily inside a conventional wheel dimensions 18 to 24 inches.

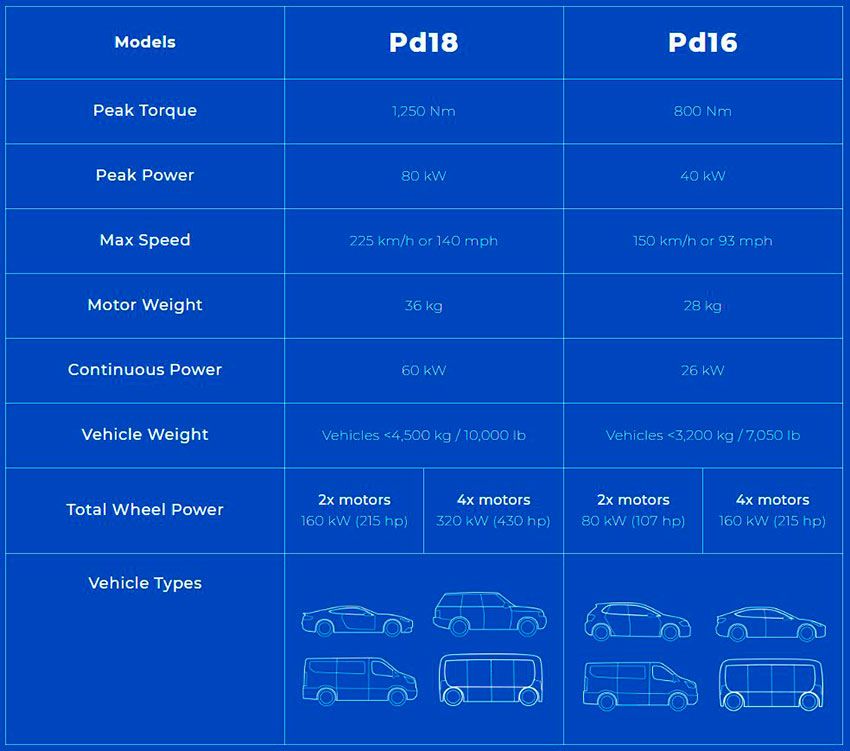

Specifications motor wheels series Pd16 and Pd18, and, even for such a powerful pickup truck like the Ford F150 is enough model Pd18

Naturally, the main advantages of a motor-wheel are available: thanks to the direct drive eliminates the need for a gearbox, drive shafts and differentials. Hence the reduction of friction losses when transferring the torque, which is essential for energy savings and increased mileage without recharging. According to its Protean Drive wheel motor can improve fuel efficiency by more than 30%, depending on the size of the traction battery and driving conditions.

The signing of the agreement on creating a joint venture with Weifu Group said, "Human Horizons

Chairman of the company Human Horizons Mr. Ding lei said that the collaboration with the Protean Drive: "...only the beginning of our long-term strategic cooperation. We are planning to launch hybrid vehicles and to develop more innovative mobile solutions. an Advanced drive system and the unconventional location of the engine directly to the wheel of the vehicle provide excellent quality of driving and will serve as a powerful data acquisition solution, being integrated in an intelligent car".

In turn, Chen Suetsune, President Weifu Group said, "Human Horizons has a wealth of experience in automotive engineering and is among the strongest in the part of innovation teams in the industry. More than 30 years of experience of the company, Weifu Group in auto parts production customizes its continuous improvement of production, and building a reliable resource supply chains, and increase investment in new technology."

In addition, the informed firm Protean Electric has previously announced a strategic partnership with the company LM Industries – maker of unmanned electric Shuttle Olli.

Initially the partnership will focus on providing system eDrive for Olli, and on the development of new technologies to accelerate future production of Autonomous cars and how the so-called "digitized", i.e. connected vehicles.

Unmanned Shuttle Olli developed by LM Industries with the use of motor-wheels Protean Electri

The LM Industries founder John B. Rogers Jr. said: "Open platforms are an important element of the strategic vision LM Industries, which allows us the flexibility to work with such innovative companies as Protean Electric, and quickly integrate new technologies that will allow us to create a great product".

CEO of Protean Electric Ki Chan, in turn, stressed: "LM Industries brings the latest technological achievements and secure mobile products. Their main ability is the rapid development and product commercialization. We fundamentally believe that our engine technology is a key tool for Autonomous passenger transport".

Transport of the future (as, for example, this new concept-space Shuttle KIA R. E. A. D., which debuts at electronics show in Seattle in January 2019) without motor wheels no cost

.

|

|

|

Element was not found.