Technology motor wheel took the next step

13 May 2019

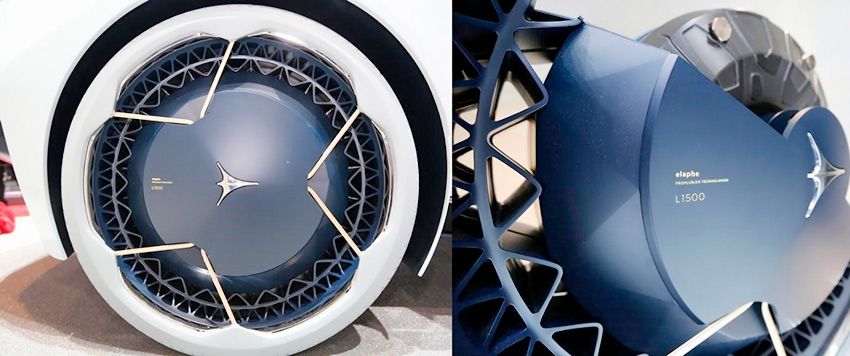

Elaphe L1500 – first serial direct-drive motor-wheel

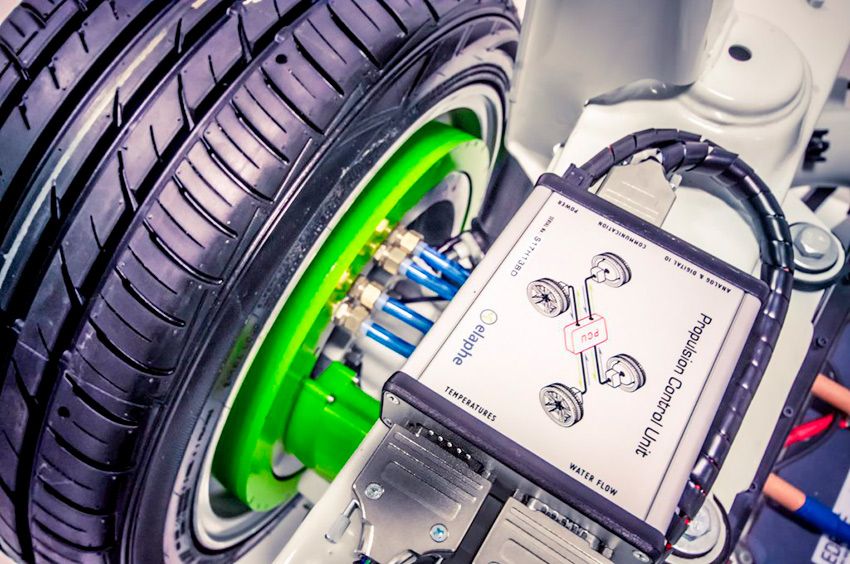

Known as the most compact and economical type of electrotransmission is the motor-wheel, where traction motor is integrated directly into the wheel hub without intermediate elements of the drive, but... one of the main problems of this "active wheel" still was the need for internal gears reducer, which allows to synchronize high-speed electric motor rotating with a much smaller number of revolutions of a vehicle wheel.

Of course the gear weighed a lot and this has led to the increase in unsprung mass suspension and reduced efficiency, and thus neutralized all the advantages of the system, despite the fact that ideally, it should have been completely relieve the designers from the problems with the internal layout and weight of the electric vehicle, and increase its maneuverability. And now, it seems that this long-standing technical problem became a step closer to the solution.

The Slovenian company Elaphe Propulsion Technologies begins mass production of direct drive of electric transmission L1500.

The motor wheel Elaphe L1500 reaches the highest in the market values of torque for traction motors producing maximum torque of 1500 N•m without using any gears.

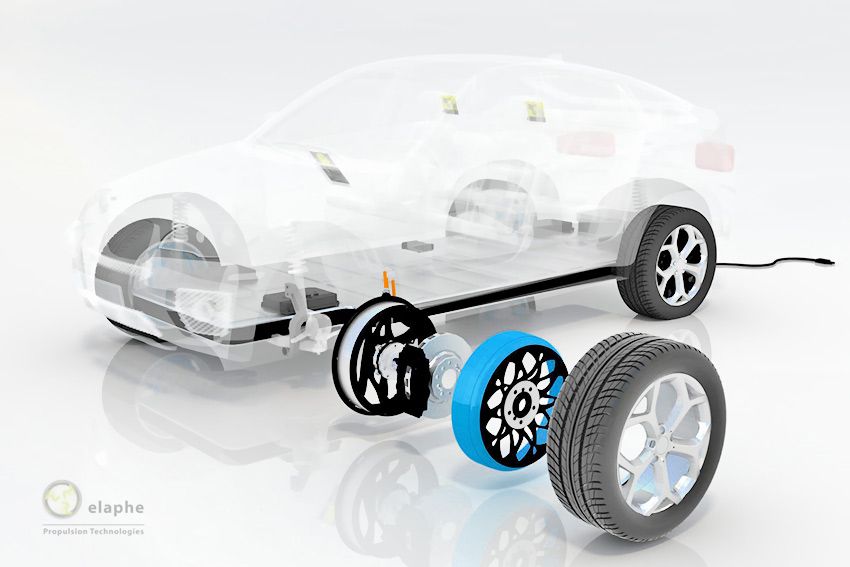

The maximum power of the motor in the motor-wheel can reach output power of 110 kW (147 L.C.) and fits into the wheel rim dimension 19 inches or more. The motor wheel L1500 compatible with all types of drive: rear-wheel drive, front or all-wheel drive. Accordingly, with such a motor-wheel can be done easily and with all the vehicle steered wheels, and is also easy implementation of regenerative mode, and the application of all the modern active safety systems, from ABS to thrust vector control.

Engine Elaphe L1500D has a unique compact, circular arrangement around the standard steering knuckle and friction brake systems.

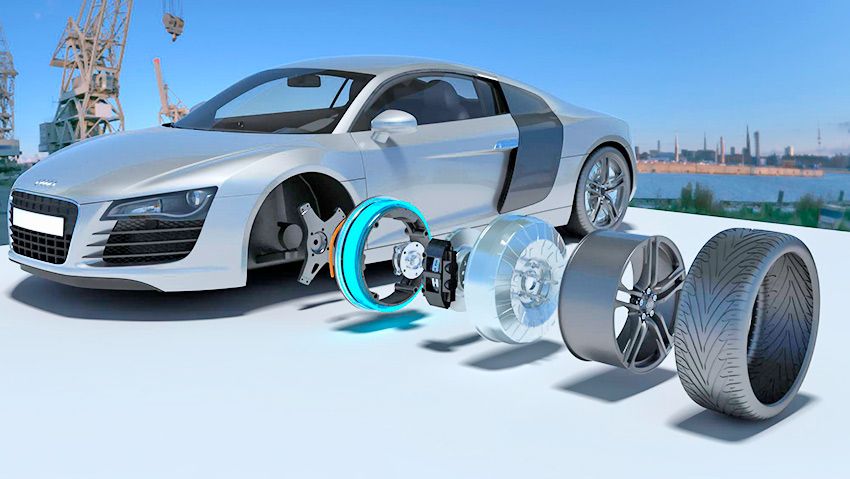

High-performance motor wheel Elaphe designed for integration into vehicles ranging from small hybrids and electric cars to SUVs and light commercial vehicles, almost without alteration and upgrading in production of wheel hubs and other mechanics of the chassis.

The most notable features of the motor wheels Elaphe is the combination of their extremely high torque, low weight and unique in its compact circular layout around the standard steering knuckles and brake systems normal.

The motor wheel L1500 D-series has been optimized for small batch production, and its earlier version has been tested on several types of vehicles, including cars and SUVs. Company expands serial production of small batches such motor wheels from the fourth quarter of 2019.

Previously, the company Elaphe demonstrated prototypes of the "mules" on the platform Smart ForTwo, crossover BMW X6 and the Audi R8 supercar, including demonstrating workable solutions for traction motors with direct wheel drive.

During a recent track test of the transmission L1500 on a modified prototype of the electric car, it accelerates from zero to 100 km/h in 3.5 seconds, a record for the vehicle transmission motor-wheels.

Company Elaphe is currently working on similar prototypes with other major car manufacturers, as well as small and starting companies-manufacturers of electric vehicles (startups), and is actively seeking partners willing to new philosophy of the layout of the vehicle, which frees up space for passengers and cargo without a complete change the existing architecture of the chassis and the brakes..

|

|

|

Element was not found.