Nissan made robots to become a tinsmith

4 October 2019

Nissan Motor company has developed advanced technology for manufacturing steel body parts for Oldtimer

The main problem for recovery of bodies already discontinued models of cars (Oldtimers) is often the lack of spare parts, and tooling (ie stamps) for their production usually have long surrendered to the scrap. So, here is the Japanese company Nissan has tackled this problem in the highest 4.0 version.

The axiom of the economy of modern automotive production – the most expensive and responsible a snap – in is exactly the body dies, which are so complex and therefore expensive that the cost of their creation kicking (in this case, just the truest sense of the word) only in the release of hundreds of thousands of identical parts. For small-scale models, and especially the restored old-timers, it's still done the old fashioned way (tE. technology for nineteenth XIX century) – hand punch steel sheet manual wooden mallets for forming the blanks (personally to watch this magic was awarded in 2016 at car factory ZIL, which uses such technology that is – ed.).

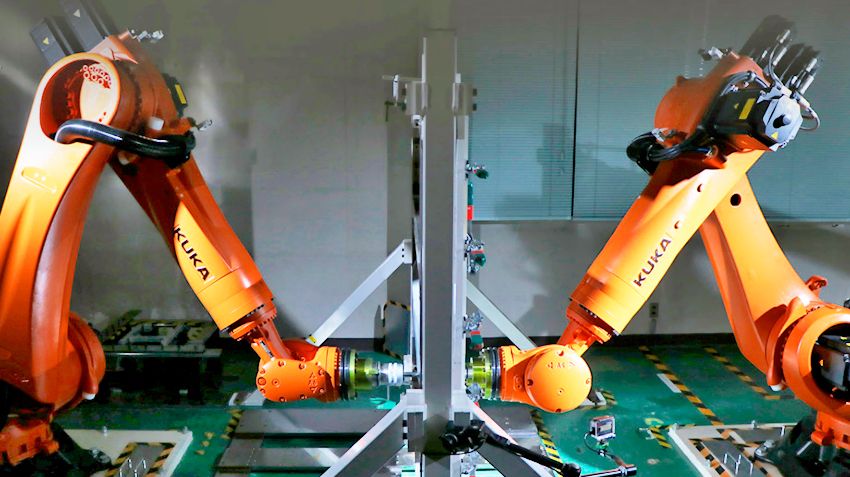

Nissan decided to automate the process of creating a unique body parts, creating after 5-year effort, the technology bashtanova double-sided sheet metal forming simultaneously (and synchronously) two manipulators

This steel sheet is mounted in a frame like a canvas to create paintings that draw from one side, but gradually squeezed from both sides by applying to the sheet in certain neighboring points of the tools with diamond tips robots acting naturally according to a certain program which is based on CAD data (CAD), in turn, created according to the Creator of the technology Manager Keigo oyamada by the translation of 2D drawings into 3D data, or by scanning the desired parts. This will allow us to produce small quantities of parts even after the disposal of stamps.Until now this technology was considered too complex to automate and costly to commercial art (i.e. art identity – ed.). But Nissan has managed to develop advanced software application for synchronous operation of two controllers, including accurate and optimal algorithm of their working movements depending on the desired shape of the part, and apply a high-strength tool with a diamond coating, which eliminates the lubrication of the treated surface. So that future restorers of the old-timers can rejoice – we need the details they will be provided.

PS Until then came progress – a work of tinsmith disappeared. Why it happened in Japan, it is manual labor in the rising sun Country roads, but young people are still not lit to become "artists-metal". On the contrary, interest in collecting and, accordingly, the restoration of the old-timers in Japan is large and growing, from here and attempt the replacement of expensive manual labour, also not cheap (watch the video) robot. Anyway, on one panel robots are by orders of magnitude longer than it would be done in several passes, and usual stamp, perhaps, of blows with a mallet too. So I think: and does that road go companions, may the future for 3D printing, although, Yes, it is for the big and flat pieces it is not as effective, besides the difference between plastic and steel parts for restorers and collectors still quite significant..

|

|

|

Element was not found.