Mazda begins mass production of engines in Russia for Japan

19 June 2019

JV "MAZDA SOLLERS" has started serial production of engines in Vladivostok and their exports to Japan

JV "MAZDA SOLLERS" mastered serial production of engines Mazda SkyActiv-G at the plant in Vladivostok, and immediately begins and the products are shipped directly to Japan for the needs of enterprises Mazda Motor Corporation.

The investment project for the production of engines Mazda implemented in the framework of TOR Nadezhdinskiy – annual capacity is 50 thousand petrol 4-cylinder 2-litre engines Mazda SkyActiv-G environmental standard Euro-5. Maximum engine power – 150 HP at 6000 rpm, fuel consumption is 6.0 l/100 km.

Within a few months, the company carried out commissioning of the equipment and production of pilot batches of products, which together was attended by Russian and Japanese engineers. Check the quality of the engines took place under the careful supervision of a team of experts "MAZDA SOLLERS" and Mazda Motor Corporation engineers.

The first test batch of engines, apart from a few mandatory tests on the line, passed specialized inspection in Japan, including testing of some of the pieces to complete the resource wear. Only after successful completion of testing of all engines from the pilot episode, they were found to be fully compliant with all international quality standards, the company Mazda. Start of series production of engines took place exactly in accordance with the project implementation schedule.

Engines Mazda SkyActiv-G is now recognized as one of the best in the world for the parameters of power and efficiency. Mazda engineers managed to achieve this through the use of advanced technologies change the work cycle of the engine.

Since the start of the serial production of 100% of the volume of engines produced will be shipped for export to Japan for automotive company Mazda.

Chairman of the Board of Directors of JSC "SOLLERS" Vadim Shvetsov has noted: "the uniqueness of the project lies in the fact that the production of engines Mazda became the first high-tech project in the far East, fully intergrown in the global value chain of major international concern. This is a great breakthrough, in terms of recognition of competencies, investment attractiveness and the competitiveness of our production sites in the far East".

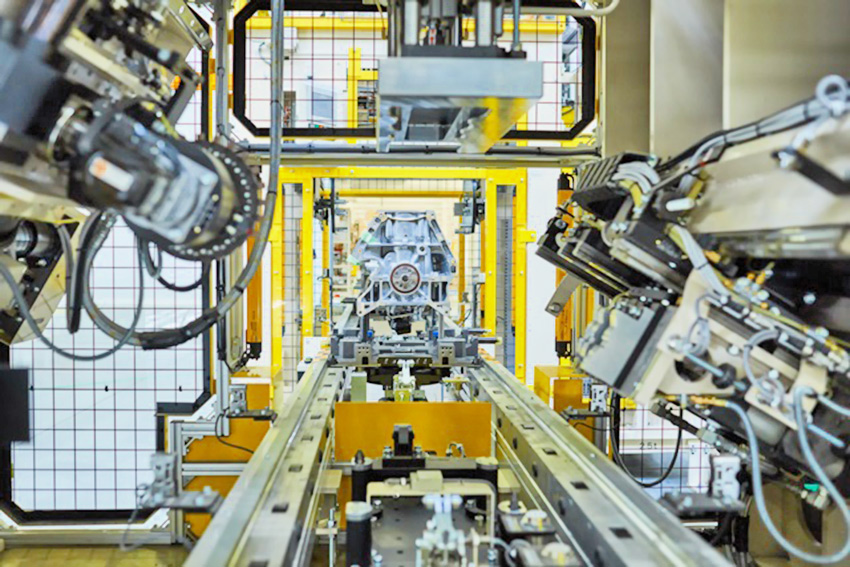

Production line of engines Mazda SkyActiv-G is a modern engineering design with a set of advanced production equipment including robotic stands and automatically guided cart (AGV). To standardize the execution of manual operations on the line were introduced such systems like Poka-yoke, Tool position system (TPS), Lamp piking system – completely eliminates any possibility of operator error in the configuration of the line connections in the engine design, as well as the performance of other operations stipulated by the technological process.

The hardware checks all the transactions carried out with the engine. In case of violation of a sequence of at least one of the operation or deviation of at least one parameter from a standard, the equipment stops the process and displays information about the error.

Also in line with modern benches for dynamic tests, which simulated various load and extreme operating conditions..

|

|

|

Element was not found.